Charcoal Briquette Machine | Coal Press Machine

| Model | WD-CB180 |

| Capacity | 1000kg/h |

| Power | 22kw |

| Dimension | 2250*1400*600mm |

| Weight | 1300kg |

| +8617329326135 |

The charcoal briquette machine also called the coal press machine, which uses the principle of screw extrusion to compress the prepared coal powder or other raw materials into briquettes.

The charcoal rods made by the charcoal briquette making machine have high density and high calorific value, so they are mostly used for barbecue charcoal or home heating and have high economic benefits.

In Africa, Southeast Asia, and other countries, due to a large amount of wood and the influence of food culture, the demand for charcoal is very large, and the charcoal briquetting machine is very popular in the market.

Raw materials of charcoal briquette machine

The main raw materials of the charcoal extruder machine are carbon powder, coal powder, cow dung, grass powder, cultured bacteria, and so on.

The raw materials need to be prepared in advance, and water and binders are added to different raw materials in a certain proportion.

For example, 100 grams of carbon powder plus 30 to 40 grams of water, and 5 to 10 grams of the binder.

How does the charcoal briquette machine work?

Charcoal extruder machine structure

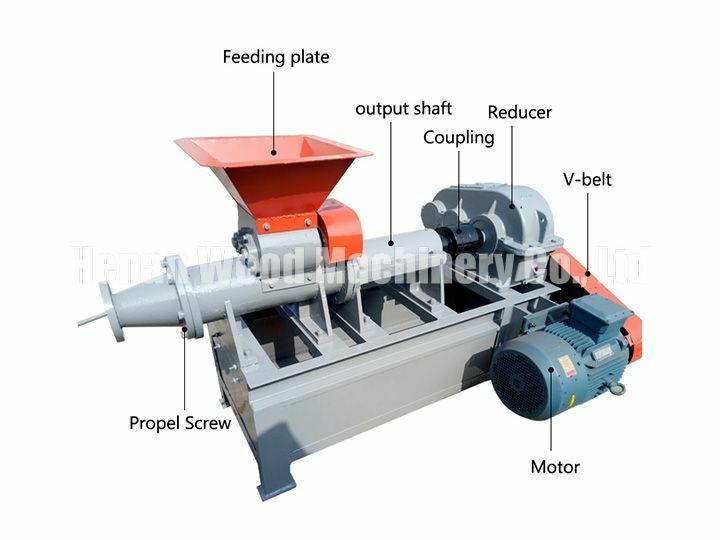

The coal press machine mainly includes a feeding port, a reducer, propel spirals, an output shaft, and a motor. The shaft seat and the machine body are rigidly connected with high concentricity.

Each part has been debugged many times to help the whole machine run stably.

Component of charcoal extruder machine

The spiral of the charcoal briquette machine is composed of three sections, and the front section can be inserted into a stick to control whether the finished product is hollow or solid.

When replacing the screw, only the front part is replaced.

There are various shapes of model dies for charcoal briquette machines, which can extrude different shapes of charcoal briquettes.

The charcoal briquette machine uses a hard tooth surface reducer, which is small in size and has a strong bearing capacity.

Working principle of coal press machine

The charcoal briquette machine makes powdered raw coal into different shapes.

Its working principle is: the electric motor transmits the power to the transmission through the belt pulley to drive the propulsion shaft to work, and the screw propeller on the propulsion shaft pushes the coal material and pushes it through the forming die to produce an ideal high-pressure coal stick.

Parameters of charcoal briquette machine

| Model | Capacity | Power | Dimension | Weight |

| WD-CB160 | 500kg/h | 11kw | 2050*900*1250mm | 900kg |

| WD-CB180 | 1000kg/h | 22kw | 2250*1400*600mm | 1300kg |

Operation precautions of charcoal extruder machine

No matter how superior the performance and quality of the coal briquette machine is, all machines need to be maintained after a period of use. Only in this way can the service life of your charcoal briquette machine be extended. The precaution of charcoal briquette machine is also important.

- Before initiating the charcoal extruder, ensure the smooth operation of the rotating components and check for any unusual noises. Allow the empty machine to run for 2 to 3 minutes before commencing production.

- Prepare the raw materials, ensuring their maximum particle size is below 3mm. Introduce water, binders, curing agents, and thoroughly mix. Let the mixture stand for 24 hours before use.

- In the event of a feed opening blockage, use wooden or bamboo strips for clearance. Strictly avoid the use of metal rods.

- Regularly lubricate the bearings in the rotating components of the charcoal briquette machine with appropriate oil. Ensure the temperature of the bearing parts does not exceed 60℃.

- When ceasing operation of the charcoal briquette machine, halt the unloading process first. Stop the machine only after the material within the cylinder is fully discharged. Disassemble the machine head and reinstall it after a thorough cleaning.

Different cutting methods of charcoal briquette press machine

The video shows the three different charcoal cutting methods of briquette machines, they can cut the briquette into different shapes.

1. Automatic cutter

The cutting knife in question is governed by an infrared sensor probe, allowing for precise control.

The cutting length can be easily adjusted to meet specific requirements as needed. The commonly used diameter is 10-12cm. The shortest diameter is 5cm.

2. CNC charcoal cutter machine

This cutter adopts a CNC numerical control system, and its length range is very wide, ranging from 3-40cm, the shortest can be 2.5cm.

This cutter is not easily affected by the environment, strong light, and dust during the cutting process, and the finished product has a stable effect. Its small size saves space during transportation.

3. Cubic charcoal briquette cutting machine

The coal cut by this cutter is a square cube with an edge length of 2.5 cm. It is mainly composed of hob and baffle.

The standard configuration is a 1.5-meter conveyor belt, and the length of the conveyor belt can be customized.

Evaluation standard of charcoal briquette quality

To ensure that the coal or charcoal rods made by users are of high quality, WOOD machinery will introduce you to the quality measurement standards of coal press machines. Such as the charcoal briquette appearance and using effect of the briquette.

More than that, we will teach you from which aspects to improve the quality of the products.

How to make high-quality coal briquettes?

The quality of the finished coal briquettes affects the price and durability. As a user of a coal press machine, everyone wants to improve product quality. So are there any methods to improve the quality of coal sticks? Sure there is.

One of the most important factors is the size of raw materials. Ensure that the size of the pulverized coal powder is less than 8mm, and the charcoal powder is less than 1mm.

Comparison of sawdust briquette machine and charcoal briquette machine

Because of the similar outlook and name, some customers are always confused about them. WOOD machinery will introduce the differences between a sawdust briquette machine and a charcoal briquette making machine.

Raw materials

The sawdust briquette machine copes with small wooden or biomass chips, like sawdust, rice husk, and bamboo chips, which are 3mm to 5mm. The raw material can also be logs or large branches, then they will be crushed by a drum wood chipper or wood hammer mill first.

However, the raw materials of charcoal briquette should be coal powder, which has been mixed with water and adhesive in advance.

Working principle

The sawdust briquette machine makes biomass stick by high temperature and pressure. At the end of the die head, there are three heating circle devices to heat the biomass stick.

The coal pressing machine has no heating device. The density of the pulverized coal is increased by spiral rotation and extrusion, and the pulverized coal is formed through a die.

Final products

There are some pictures you can see below. It is pronounced that products made by sawdust briquette machines are yellow wooden sticks, meanwhile, products made by charcoal extruders are black coal sticks.

Why is the charcoal briquette machine so popular?

The sales of WOOD machinery charcoal extruder machines continue to maintain a momentum of growth. Investigating the reasons for this, the industry expert gave us the following analysis, which can explain why charcoal extruder machines are so popular.

To begin with, there are many types of raw materials fit to the charcoal briquette machine. Such as charcoal powder, coal powder, and grass powder.

Secondly, the price of the charcoal extruder is not high, the small investment can make a big profit.

Last but not least, the density of bar charcoal is more than 3 times that of ordinary log charcoal, it burns without smoke, has a calorific value of 5500-7000 kcal/kg, and has low ash content.

Because of the above features, the market application range of charcoal rods is very wide.

Common mechanical failures and solutions of charcoal briquette machine

Any machine will have various problems during use, and we also have corresponding measures for them.

When it comes to a coal press machine, after using the machine for a while, the staff should check the bearings. The bearing of the coal rod machine is damaged or does not operate normally, which will increase the load of the motor, and it is easy to burn out the motor for a long time.

As a solution, the factory should check the bearings of the coal rod machine on time to see if there is any damage, and the old parts should be replaced in time to avoid affecting the normal operation of the machine.

How to prolong the service life of a charcoal extruder machine?

All machines need to be maintained after a period of use, no matter how superior the performance and quality of the coal press machine are. Only in this way can the service life of your machines be extended, and the quality of the coal sticks produced can be ensured.

There is some advice to prolong the service life of a charcoal extruder. Including maintaining the feeding part of the machine and maintaining the bearings of the various parts of coal briquettes.

Our successful case of an Iraqi customer

Our company’s charcoal briquette extruders are very popular and have been exported all over the world. Recently, we had a successful case with a customer in Iraq.

Our customers in Iraq consulted us about charcoal briquette making machines, our sales manager Beco learned that he was just starting the coconut shell charcoal business and wanted to try it first to see how it works, so Beco recommended WD-CB180 to him for its moderate yield.

Finally purchased two of them and one charcoal pulverizer. Now those machines have been shipped to Iraq.

Shuliy’s charcoal briquettes extruder for sale

Shuliy’s charcoal briquettes extruder employs the unique principle of screw extrusion to compress meticulously prepared coal powder or other raw materials into high-density, high-calorific-value charcoal rods.

Proudly, our company stands out with innovative technology, efficient productivity, and a steadfast commitment to environmental sustainability. Whether you’re aiming for increased output or focused on reducing environmental impact, the Charcoal Briquette Extruder stands as a reliable ally for the success of your venture.

Now, click below to reach out to us and delve deeper into information about the Charcoal Briquette Extruder. Embark on a journey of deliciousness and sustainability.