Wood Pallet Block Production Line | Sawdust Brick Making Machine

| Brand | WOOD Machinery |

| Raw materials | Sawdust, wood chips |

| Main equipment | wood crusher, dryer, wood briquette making machine |

| Warrranty | 12 months |

| +86 19139754732 |

The wood pallet block production line uses sawdust, shavings, straw, and other waste materials as raw materials. After crushing, drying, and mixing glue, it is heated and pressurized by a sawdust brick making machine to produce pallet foot blocks. The wooden pallet block formed by high temperature and high pressure has a smooth and flat appearance, high hardness and favorable price. It is an ideal product for making wooden pallet feet. The size of the wood briquette making machine can be customized according to customer needs, and the pressure and density of the woodblock can also be adjusted.

Raw materials of wood pallet block production line

The raw materials of the sawdust brick production line are very wide, mainly including wood chips, shavings, straw, etc. These raw materials are generally leftovers from furniture factories and wood processing factories, which are low-cost and easy to collect. These raw materials need to ensure that the size is 6-8 mm. If they are not satisfied, they should be pulverized by a pulverizer. The drying degree requires that the moisture content is less than 12%, which can be processed by a dryer.

Main steps in wood brick production line

There are mainly four steps in the wood pallet block production line, the specific equipment and requirement are following.

Step 1: Pulverizing ( Wood hammer crusher)

In order to ensure the hardness and smoothness of the woodblock after forming, when the size of the raw material is larger than 8 mm, a pulverizer is required to pulverize the wood chips or shavings to 6-8 mm.

Step 2: Drying ( Biomass rotary dryer)

The pulverized wood chips should be further dried by a biomass rotary dryer specially designed to dry wood chips, and the wood chips with a moisture content of less than 12% can be processed in the next step.

Step 3: Gluing (Glue mixing machine)

Mix the special glue that accounts for 16-20% of the raw materials with the dry wood chips, and use a glue mixer to mix them thoroughly. This step will increase the viscosity of the raw materials and facilitate subsequent molding.

Step 4: Forming (Wood briquette making machine)

This is the most important step of the whole production line. The mixed raw materials are poured into the sawdust brick making machine, and the sawdust is pressed into wooden sticks by high temperature and high pressure.

These sticks have high density and high hardness. After cutting, they can be used as foot piers for wooden pallets.

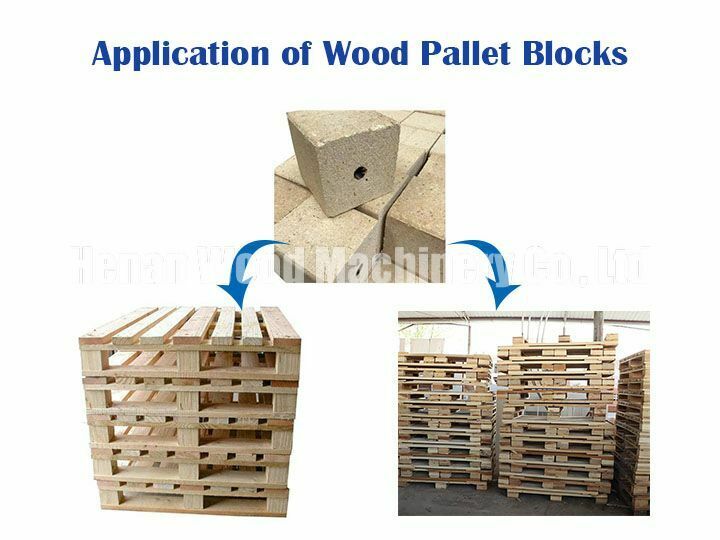

Sawdust brick making machine application

The wood pallet blocks are mainly used as an important part of fumigation-free pallets and packaging boxes. It is very popular with customers because of its strength and the characteristics of replacing logs and beautiful appearance.

The brisks made in this production line are free of fumigation, which have a lower price than solid wood blocks. The process is simple, which only includes four pieces of equipment with large output. The color of wood blocks is a similar color to the panel. The pallet block production line uses waste raw materials to save forestry resources. Because of its outstanding price advantage and environmental protection characteristics, it has been valued by the packaging industry.

Advantages of wood pallet block production line

1. We can offer different kinds of cutting devices for the wood briquette making machine according to customers’ demands.

The multi-blade saw can cut the wooden sticks into the same size at the same time, with high cutting efficiency and large workload, which is more suitable for large-scale processing plants.

The dual-blade saw has two sharp blades, which have a strong cutting ability, and can cut wood with smooth edges. It is the best choice for small pallet processors at an affordable price.

2. One glue mixing machine can support the raw materials of two sawdust brick making machines, and the processing plant can use multiple machines to work at the same time according to its own output. In this way, the plant can improve production volume and production efficiency.

Loading and delivery of sawdust brick production line

Our Indonesian client is a wooden pallet manufacturer, and he is also an environmentalist. The forest resources are rich in his country, but he did not choose solid wood pallets but used recycled wood chips as raw materials.

After fully investigating our After building the factory, he chose to invest in an environmentally friendly wood briquette production line. The output of the sawdust making machine is 4-5 m3/24h. He told us that these wooden pallets can still be recycled and reused after they are worn out.

Factory stove of wood briquette making machines

We have enough machines in stock, if you are interested, welcome to consult wood pallet block production line, our sales manager and technology center will design and provide the most suitable production line for you.