Sawdust Briquette Machine | Biomass Briquette Machine for Sale

| Model | WD-WB50 |

| Capacity | 250-350kg per hour |

| Power | 18.5kw/22kw |

| Dimension | 1.7*0.7*1.4m |

| Weight | 700kg |

Wood briquette making machine, often referred to as a sawdust briquette machine, is a device used for creating briquettes from wood materials. The biomass briquette machine mainly squeezes rice husk, sawdust, and waste wood chips into high-density rods under high temperatures and high-pressure conditions.

Nowadays, waste utilization is highly praised by many environmentalists, the raw materials are all waste or worthless projects, so the machine is a piece of very environmentally-friendly equipment.

The finished wood rods can be used as fuel, which has high density, small volume, and good flammability The biomass briquettes can replace firewood and coal, or be further processed in a carbonization furnace.

Raw materials of sawdust briquette machine

The biomass briquette machine for sale can use many raw materials, including sawdust, corn stalks, soybean stalks, sorghum stalks, and other crop stalks, rice husks, grasses, branches, coconut shells, bamboo chips, etc. Almost all wood waste and farmland straw can be used to process sawdust briquettes.

However, these raw materials need to be crushed with a wood crusher first, because the humidity of the raw materials must be controlled at 8%-12%, so the excess moisture of the raw materials needs to be removed with a dryer before they can be processed by wood briquettes making machine.

Video of sawdust briquette machine for sale

Structure of wood briquettes making machine

- The control cabinet is used to adjust the voltage and temperature of the sawdust briquettes press machine, operate the screw propeller to reverse, and prevent the material from jamming.

- The motor rotates fast and has a good quality, which will help the biomass briquette machine run smoothly.

- Bearings are thicker than before, so they are more resistant to wear and help the machine work stably.

- A bigger feeding port can improve the working efficiency of the stalk briquette making machine.

- Automatic control electric heating circles can adjust the dryness and humidity of the material.

- The finished sawdust briquettes of the wood briquettes machine will drop on the chopping rack.

Sawdust briquette making machine components

The screw of the biomass briquette machine for sale has been debugged many times, the pitch is increased, and the feeding amount is increased, thereby greatly improving the output.

The designed fully automatic control electric heating device for the sawdust briquette machine for sale can adjust the dryness and humidity of the material.

It can ensure the stability of the discharging and forming and improve the work efficiency of the sawdust rod-making machine.

Common molds of the sawdust briquette machine for sale are hexagonal or quadrilateral, and special shapes can also be customized according to customer needs.

Through continuous debugging, our factory successfully improved the structure of the forming cylinder, reduced the friction between the biomass briquette machine and the raw material, and increased the density of the briquettes.

Principle of biomass briquette machine for sale

When the sawdust briquette machine is working, it needs to be preheated to 380 degrees Celsius, and the raw materials are placed at the feed port after the temperature is reached.

Driven by the motor, the bearing, and screw conveyor push the material smoothly into the forming tube, and the wood chips or rice husk are extruded from the discharge port through the extrusion of high temperature and high pressure.

Features of sawdust briquette machine final products

- The common size of compressed sawdust briquettes made by biomass briquette machines is 40cm or 50cm, and the minimum length that the wood briquette making machine can make is 15cm.

- These compressed sawdust heat logs have the advantages of high density, small size, good combustibility, etc. It can replace fuelwood and coal and is very suitable for family fireplace fuel.

- In the production process of turning sawdust into briquettes, the sawdust biomass briquettes are squeezed by high temperature and high pressure, and the middle of the sawdust biomass briquettes is hollow, which is conducive to the evaporation of water vapor. Generally, the outer diameter of the product is 50-60mm, and the aperture is 15-20mm. The biomass briquettes’ shapes always are hollow quadrilateral, hexagonal, octagonal, or circular.

- Well-compressed sawdust heat logs have no cracks on the outside, and the color is wood yellow with no burnt color. Operators can improve the quality of the finished product through multiple adjustments.

Parameters of biomass briquette extruder

| Model | WD-WB50 |

| Capacity | 250-350kg per hour |

| Power | 18.5kw/22kw |

| Dimension | 1.7*0.7*1.4m |

| Weight | 700kg |

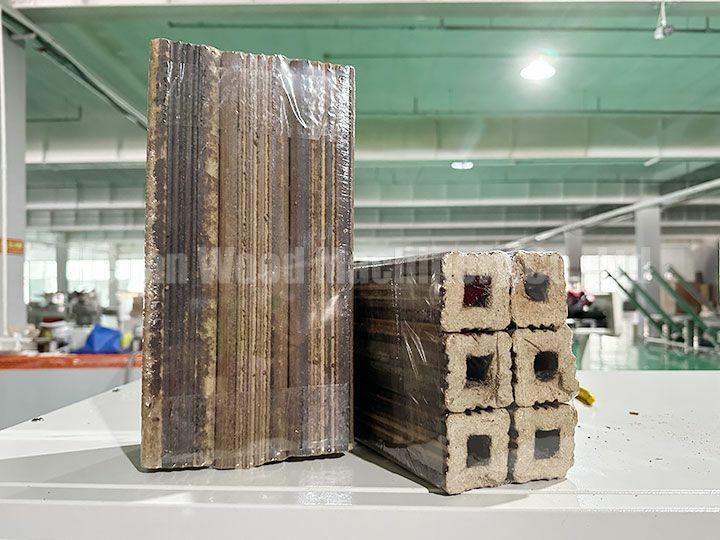

How to pack sawdust biomass briquettes?

Our company also provides professional briquette packing machines, after the production of sawdust briquettes by the biomass briquette machine, the factory can use the charcoal packing machine to wrap the bio-briquettes according to the quantity.

The packaged briquettes are not easy to change moisture, and they will be more convenient to transport. The packaged compressed sawdust briquettes are also beautiful in appearance and welcomed by the market.

Those are the packaged sawdust briquettes.

Complete biomass briquette production line

The sawdust briquette machine will work more efficiently in the biomass briquette production line, which includes a series of products, such as wood shredders, dryers, and sawdust briquette machines for sale.

The main step of the sawdust biomass briquette production line includes initial coarse crushing–fine crushing–drying sawdust–cooling sawdust–sawdust briquette forming–carbonization.

Various logs, miscellaneous woods, furniture leftovers, etc. are crushed and dried into sawdust sticks through a series of steps. As a professional manufacturer and supplier of biomass charcoal machines, the WOOD factory can customize related equipment and provide domestic and foreign customers with overall processing solutions at preferential prices.

A complete charcoal plant installed in Guinea

Our company has shipped a complete charcoal production line to Guinea, among which the most important machines are five sawdust biomass briquette machines. The final products of the charcoal plant in Guinea are carbonized biomass briquettes.

We have sent one engineer to Guinea to assist in the installation of the charcoal production line. Now the customer has finished the installation and began to produce charcoal briquettes.

Factory packing real shot of sawdust briquette machine

Can bark and leaves be used to make sawdust biomass briquettes?

After purchasing a sawdust briquette machine, it is also important for customers to consider whether the following raw materials are suitable for processing charcoal briquettes. An Indonesian customer consulted us when they purchased our sawdust briquette machine. There are many trees near their factory, and many pruned branches and leaves were burned directly.

Considering the perspective of environmental protection, they asked if they could use leaves or barks to make charcoal. In fact, there are many raw materials that are suitable for making charcoal. including sawdust, corn stalks, leaves and barks can also be used to make biomass briquettes, but they need to add some other materials like sawdust.

Global cases of biomass briquette machines for sale

Sawdust briquette machine shipped to Myanmar

Recently, we shipped a whole biomass briquette production line to Myanmar. Our client in Myanmar is a businessman who does a charcoal business. He has his own charcoal processing factory locally. In the process of looking for a seller, he saw our charcoal machine channel on YouTube, so he contacted our sales manager and said his needs.

After constant communication with the sales manager, the customer chose our sawdust briquette machine, wood crushers, a carbonization furnace, and related auxiliary equipment.

More successful cases of sawdust briquette machine

Our biomass briquette machines have been sold all over the world, and they helped charcoal plants and wood processing plants everywhere to make sawdust biomass briquettes for profit.

If you have the same requirement, welcome to consult us anytime.

Invest in Shuliy’s wood briquette extruder

In conclusion, with our cutting-edge wood briquette extruder machine leading the way, we are committed to delivering efficient and reliable solutions for wood processing. Our machine not only effectively transforms wood waste but also provides an environmentally friendly and sustainable fuel option.

Whether you are seeking a solution for wood processing or aiming to convert wood waste into a valuable resource, our company is the trusted partner you need. Contact us now to explore innovative solutions for your production and environmental goals.