Wood Shaving Machine for Animal Bedding | Wood Log Shaver Machine

| Model | WD-WS420 |

| Input Size | 6cm |

| Power | 7.5kw |

| Capacity | 300kg/h |

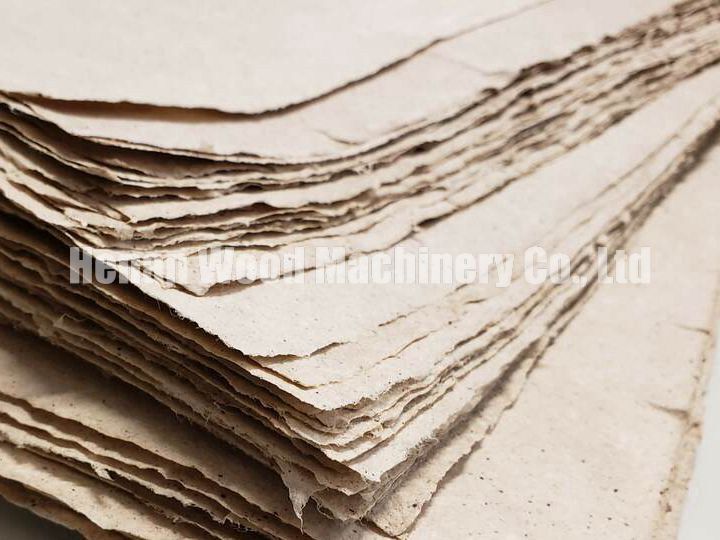

The wood shaving machine can make logs, branches, sticks, and boards into wood shavings. It is an ideal machine applied to shaving board plants, board plants, board mills, and paper-making plants. The final products can be used for animal bedding, medium, and transportation, etc. With a processing capacity of 300–2500 kg/h, it meets both small-scale and large-scale production needs.

Our power unit has two methods: electric motor and diesel generator. To collect the final materials well, it can be equipped with a conveyor belt to transport these wood shavings into a certain place. Furthermore, we support customization services according to specific requirements.

Raw materials of wood shaving machine

The raw materials of the wood shaving machine are logs, wooden boards, branches, etc. Usually, manufacturers who are used to making high-quality pet products use logs that have been peeled with a wood peeling machine.

The shavings produced by doing so have a uniform color, stable quality, and higher profit margins. In addition, paper manufacturers also use wood that has been barked.

Log shaver machine structure

The wood shaving machine is mainly composed of the main body of the frame, inlet, outlet, blade, motor, and so on. After raw material enters the machine body through the inlet, the blade will cut the wood into shavings and finally be discharged through the outlet. The whole working process is very fast, making mass production possible.

The size and thickness of the shavings are changeable by adjusting the length of the blade and the degree of inclination of the blade to meet the needs of different customers. Besides, the position and length of the inlet and outlet also can be customized according to the requirements.

Features of wood shaver machine

- By adjusting the inclination angle of the knife, the thickness of the shavings can be adjusted. The size and thickness of the finished product can be adjusted flexibly to meet various needs.

- The wood shavings processed by machines are almost the same as the wood shavings pushed out by hand planers, and the texture is very good. Using machines can greatly improve efficiency and save labor costs.

- The structural design of the machine and the manufacture of components are all made by our factory. The cost of maintenance is low, and the shaving machine can serve a long service life.

- The wood shaving can be used as biological fuel, fillings materials for shipping fragile things, and animal bed fillings in farm plants for cows, pigs, sheep, or all kinds of animals.

- Customization service is available. Some customers want the size of the shavings to be smaller. Our factory can provide a shavings pulverizer. The inside of the machine has hammers which can smash the raw materials into small pieces.

- The shaving machine can be equipped with a motor or a diesel engine. The diesel engine is not limited by voltage and is easy to move.

The blades of the log shaver machine

The blade of the wood shaving mill machine plays a very important part in the whole wood shaving process. The size and the thickness of the final products are related to the length and inclination angle of the blade. High-quality blades are more beneficial for the production of high-quality shavings. Our blades adopt carbon steel material, which not only has a long life but also is easy to disassemble and install.

No matter how good the quality is, it needs good maintenance for a longer service life. For large production for a long time, blades may wear out and become blunt, which will affect the effect of wood shaving. We supply special knife sharpeners, which can make the blade sharp. We provide installation videos.

Applications of wood shaving machine

The wood shaving machine has a wide range of applications. The wood shavings it produces can serve as raw materials for plywood manufacturing, wood pulp paper in paper mills, and biomass energy fuel.

In addition, these shavings are commonly used as bedding for pets and poultry, as well as cushioning material for transporting fragile goods. This makes the machine suitable not only for small and medium-sized enterprises but also for individual wood processing households.

When the cold wave and low temperature hit, the zoo opened a “warm mode” for the chimpanzees.

The ground is laid with litter such as shavings and straw to resist the cold winter.

Parameters of wood shaver for sale

| MODEL | CAPACITY | INPUT SIZE | POWER |

| WD-WS420 | 300KG/H | 6cm | 7.5kw |

| WD-WS600 | 500KG/H | 12cm | 15kw |

| WD-WS800 | 1000KG/H | 16cm | 30kw |

| WD-WS1000 | 1500KG/H | 20cm | 55kw |

| WD-WS1200 | 2000KG/H | 24cm | 55kw |

| WD-WS1500 | 2500KG/H | 32cm | 75kw |

The most popular models are 420, 600 and 800. Customers in South Africa and the Middle East use them to make wood shavings, which are often used to make nests for livestock and poultry.

Routine maintenance of wood shaving machine

- In order for the machine to run normally, the bearing should be filled with butter in time, and the planer should be filled with butter once every 3-4 hours of continuous operation.

- The inside of the machine should be cleaned before each gets off work, and the crushed materials should not be left behind, and the blades should not be stuck.

- Turn off the power after using it every day, and adjust the tension of the belt so that it drops about 8 cm.

Conclusion

Maximize wood utilization and meet the diverse needs of various industries with our wood shaving machine. Whether for woodworking, animal bedding, packaging, transportation, or energy production, our machine is indispensable.

Invest in a wood shaving machine today to unlock your production potential, enhance efficiency, and explore new opportunities for your business!