Shisha Charcoal Production Line | Hookah Charcoal Making Machine

| Wood crusher | Model: SL-80 Power:37+7.5kw Capacity:1500-2000kg per hour |

| Rotary dryer | Model: SL-R1000 Power:7.5+7.5kw Capacity:800-1000kg per hour Dimension:φ1*10m |

| Charcoal grinder | Diameter:1.5m Power:7.5kw |

| Charcoal briquette machine | Model: SL-180 Power: 22kw Capacity: 800-1000kg per hour Dimension: 2200x1400x600mm |

| Carbonization furnace | Model: SL-C1500 Dimension:4.5*1.9*2.3m Capacity:4-5t per day |

Shisha Charcoal Production Line encompasses a range of specialized equipment designed for the efficient production of high-quality hookah charcoal. This comprehensive line includes essential components such as a carbonization furnace, wood hammer mill, charcoal powder mixer, hookah coal making machine, charcoal drying machine, and packing machine.

Hookah Charcoal Making Machine caters to the demand for various shapes and sizes of hookah charcoal, including round briquettes, cubic forms, and options for customized patterns. The production capacity, customizable from 100kg/h to 1t/h, ensures flexibility to meet diverse customer requirements.

Shisha Charcoal Production Line is mainly used to produce high-quality hookah charcoal, which is very flammable and smokeless. The finished product is tasteless with high density and low ash, which is an ideal product for hookah lovers to light tobacco.

Applicable raw materials of hookah charcoal production line

The first step in producing high-quality hookah charcoal is selecting the right raw materials. Let’s delve into the materials best suited for this process.

The raw materials of the hookah charcoal production line can be nutshells, small wood chips, or large logs, branches, bamboo, coconut shells, etc.

Nowadays, coconut shell hookah charcoal is more and more popular in the industry, because its finished product has high hardness, high density, and long burning time, which can meet the requirements of superior waterpipe charcoal.

With the right raw materials in hand, the next step is to understand the overall process of producing shisha charcoal.

Brief introduction of shisha charcoal production steps

Carbonizing raw materials — Crushing carbonized materials — Mixing charcoal powder, water, and adhesive — Hookah coal forming — Drying — Packaging

Main equipment of the shisha charcoal production line

Now that we have an overview of the production steps, let’s take a closer look at the main equipment required to carry out these steps efficiently.

Carbonization furnace

If the raw materials for carbonization are logs, large pieces of wood, branches, etc., then use a hoist carbonization furnace or a horizontal carbonizing machine.

If the raw material is nutshells, small thin wood chips, or rice husks, we recommend using a continuous carbonization furnace. We will also recommend suitable carbonization furnaces according to customers’ different output requirements.

Recently, our factory has the latest carbonization furnace. The combustion chamber of the newest charcoal-making machine is designed with ceramic fiber, which has a good thermal insulation effect and has a service life of up to 12 years, avoiding secondary pollution of castables.

| Model | Capacity | Weight | Size |

| WD-HC1300 | 900-1200kg/12-14h | 2500kg | 3*1.7*2.2m |

| WD-HC1500 | 1500-2000kg/12-14h | 4000kg | 4.5*1.9*2.3m |

| WD-HC1900 | 2500-3000kg/12-14h | 5500kg | 5*2.3*2.5m |

Wood hammer mill

After the raw material is carbonized, the charcoal obtained is crushed into charcoal powder with a hammer mill, with a diameter of about 1 mm. After that, a Raymond mill is used for fine grinding to obtain fine carbon powder of 80 mesh.

We are committed to helping customers make high-quality hookah charcoal, we recommend using two types of crushers, the first coarse crushing and the second fine crushing.

Charcoal powder that reaches 80 meshes can produce hookah charcoal that is denser and more resistant to burning, and the market price is higher, helping customers achieve higher profits.

| Model | WD-HM80 | WD-HM90 | WD-HM1000 | WD-HM1300 |

| Power(kw) | 37 | 55 | 75 | 90 |

| Hammers(pcs) | 50 | 50 | 105 | 105 |

| Fan(kW) | 7.5 | 7.5 | 11 | 22 |

| Dust remover(pcs) | 5 | 5 | 14 | 14 |

| Cyclone diameter(m) | 1 | 1 | 1 | 1 |

| Power(kW) | 1.2-1.5 | 1.5-3 | 3-4 | 4-5 |

Charcoal powder mixer

The charcoal mixing machine is mainly used to mix charcoal powder, water, and binder and stir evenly. The mixture can be rolled to increase the density. It is a pre-compression before molding to facilitate subsequent molding.

| Model | WD-CG1 | WD-CG2 | WD-CG3 | WD-CG4 | WD-CG5 | WD-CG6 | WD-CG7 | WD-CG8 |

| Power(kW) | 1000 | 1200 | 1500 | 1600 | 1800 | 2000 | 2500 | 3000 |

| Feeding amount(Kg/h) | 110 | 150 | 3500 | 350 | 550 | 900 | 1700 | 2000 |

| Mix time(min) | 3-8 | 3-5 | 3-5 | 3-5 | 3-5 | 2-5 | 2-5 | 2-5 |

| Speed(r/min) | 41 | 41 | 37 | 37 | 36.1 | 35 | 30 | 30 |

| Power(kw) | 5.5 | 7.5 | 15 | 18.5 | 22 | 22 | 30 | 37 |

| Capacity(t/h) | 1.5-2.5 | 1.5-3 | 7 | 9 | 13 | 18 | 30 | 40 |

Hookah coal making machine

The hookah charcoal machine uses finely grounded charcoal to make hookah charcoal blocks.

We provide customers with three types of hookah charcoal machines, including stainless steel shisha coal machines and hydraulic hookah charcoal machines.

In addition, If you want to expand the production of shisha charcoal, or upgrade the shisha charcoal equipment, we recommend the rotary shisha charcoal machine, which has higher pressure and can produce better quality shisha charcoal.

| Type | WD-RS 21 |

| Powder Filling Depth (mm) | 16-28 |

| Max Pressure (kn) | 120 |

| Tablet Thickness (mm) | 8-15 |

| Punch Quantity (sets) | 21 |

| Motor Power (kW) | 7.5 |

| Turret rotation speed (r/min) | 30 |

| Output (pcs/h) | 30000-40000 |

| Dimension (mm) | 800*900*1650 |

| Weight (kg) | 1500 |

Charcoal drying machine

In order to better package hookah charcoal, drying them is an indispensable step. The molded hookah charcoal has a certain degree of humidity. If they are directly packaged without drying them, water vapor will be generated in the packaging bag, which will affect the combustion effect.

There are two types of hookah charcoal drying equipment, they are drying room and mesh belt dryer. The prepared hookah charcoal is placed on the shelf inside the drying room and dried by hot air circulation. The mesh belt dryer uses a multi-layer stainless steel mesh belt to transport the material. Hot air flows through the belt, effectively drying the material.

| Model | WD-BD 08 | WD-BD 010 |

| Drying room size | 8m*2.3m*2.5m | 1mX2.3mX2.5m |

| Circulating fan | 6pcs | 6pcs |

| Dehumidification fan | 2pcs | 2pcs |

| Trolley | 8pcs | 10pcs |

| Tray | 80pcs | 100pcs |

Packing machine

Exquisite packaging always strengthens people’s desire to buy, and hookah charcoal is no exception. The most common shapes of hookah charcoal are circles and squares. The dried hookah charcoal will be wrapped in a packaging machine, and the pattern and words on the packaging bag can be customized.

| Type | WD-HP 280 |

| Packaging film width | 100-280mm |

| Bag length | 80-300mm |

| Packing height | 5-60mm |

| Film roll diameter | ≤320mm |

| Capacity | 120bags/min |

| Power | 3.55kw |

| Size | (L)4000×(W)900×(H)1500mm |

| Weight | 500kg |

Supplementary machines of the shisha charcoal production line

In addition to the main equipment, there are supplementary machines that enhance the production process.

Starch blender

Due to regional constraints, some customers opt to use homemade starch as an adhesive for producing shisha charcoal briquettes.

This starch requires thorough mixing with hot water in a stirring tank before blending with charcoal powder to effectively bind the briquettes.

Storage bin

In the production line, because the amount of raw materials processed by each machine is different, it is necessary to equip a storage bin to store the raw materials processed in the previous step.

In this way, we can balance the working speed of the entire shisha charcoal production line.

For example, adding a storage bin between the pulverizer and the charcoal powder mixer is a good choice.

Feeding device

If the customer has a large output and uses several hookah charcoal machines, then in order to improve efficiency, you can choose a distribution device.

Weighing storage bin

Before mixing the charcoal powder and the binder, you can prepare one weighing device to weigh the binder according to a certain ratio, and then mix it with the charcoal powder.

With all equipment and supplementary machines in place, it’s important to understand the features that define high-quality hookah charcoal.

What are the features of high-quality hookah charcoals?

- First, good hookah charcoal must be hard and won’t break when dropped from a high place.

- Second, the density is high. Put a piece of hookah charcoal into the water. If the charcoal powder cracks, it means that its density is not high enough. High-quality hookah charcoal can sink into the water, and there will be no charcoal powder.

- Third, there is no smoke and odor when burning.

- Fourth, there is less ash after combustion.

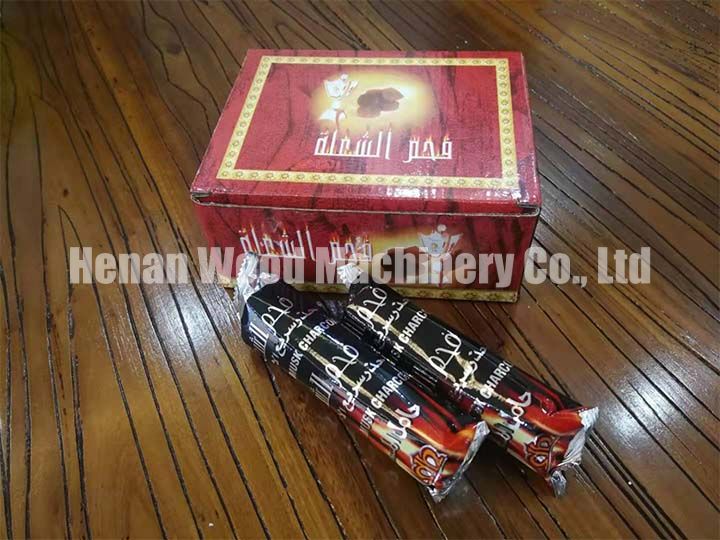

Packaged product display of shisha charcoal plant

The text and patterns on the packaging bag can be customized according to the needs of customers. Generally speaking, there are ten round hookah charcoals in a pack, 48, 72 or 96 square hookah charcoals in a pack.

Once the charcoal is produced, dried, and packed, it’s ready for distribution. Let’s take a look at how the finished products are presented.

Invest in our shisha charcoal production line

Choosing our Shisha Charcoal Production Line is not just an investment in a high-quality, efficient production system, but a gateway to new business growth opportunities. Our reliable equipment and advanced technology produce the most sought-after shisha charcoal on the market.

Whether you are a new entrepreneur or an experienced manufacturer, our production line can meet your needs and help you stand out in a competitive market. Contact us today to start your journey to success and create a brighter future together!