Box-type Charcoal Dryer | Charcoal Briquette Drying Machine

| Model | WD-BD 08 |

| Drying room size | 8m*2.3m*2.5m |

| Circulating fan | 6pcs |

| Dehumidification fan | 2pcs |

| Trolley | 8pcs |

| Tray | 80pcs |

The box-type charcoal dryer is very common in the wood charcoal industry. Usually, drying and packing briquettes are the last steps of the charcoal production line. The molding process of various types of charcoal briquettes like shisha charcoals and charcoal balls requires the addition of a certain proportion of binder and water. Therefore, the freshly produced biomass-based carbon has higher moisture content and needs to be dried to improve various strength indicators.

Application of charcoal dryer

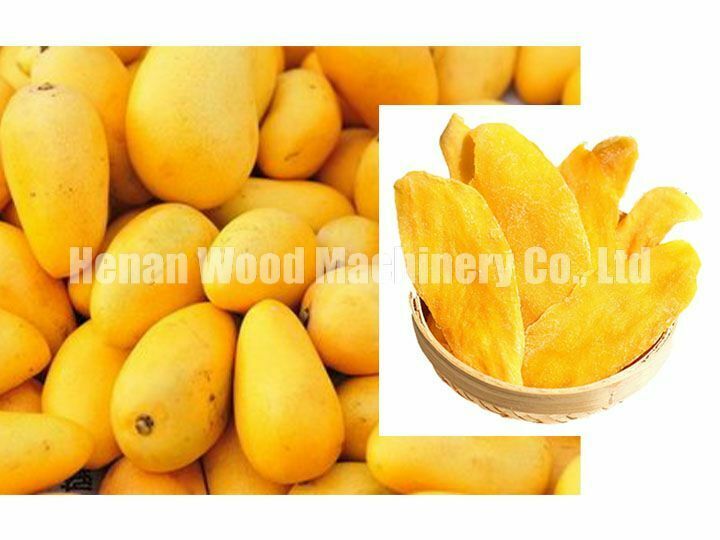

The box-type charcoal drying room has a wide range of applications and can be used in many fields such as charcoal, food, agricultural and sideline products, fruits, Chinese medicinal materials, and aquatic products. For charcoal processing plant, their raw materials are always hookah charcoal, honeycomb charcoal briquettes, BBQ charcoal balls and so on.

Due to the wide range of raw materials, food processors can also dry fruits and vegetables with this box-type dryer.

Structures of box-type charcoal dryer

The box-type charcoal dryer is mainly composed of an insulation box body, a control cabinet, fans, shelves, a ventilation duct, a temperature and humidity measurement system, and a dust removal device. The wall panels of the thermal insulation box are made of 4mm color steel at the front and back, and 7mm thermal insulation rock wool in the middle. If the heating method is heat pump heating, a heat pump must be configured.

Video of charcoal briquette drying machine

In this video, the charcoal dryer processes many kinds of raw materials like sweet potato starch, mango, and charcoal briquettes, which shows the wide raw materials of the box-type dryer.

Working principle of charcoal briquette drying machine

The heating method of the charcoal briquette drying machine mainly includes the traditional wood-burning coal-burning method and the more environmentally-friendly method of burning wood pellets can also be used. Of course, a heat pump can also be used for heating. Set different temperatures according to different materials, the maximum temperature is 120 degrees Celsius, if the charcoal is dried, the maximum temperature is 70-80 degrees Celsius.

The hot air circulates continuously through the pipes around the drying room, and in the drying box, it is heated by the hot air circulation to achieve the effect of drying the materials. The drying box is equipped with a moisture exhaust port, which can effectively remove water vapor and ensure the drying effect.

Advantages of box-type charcoal dryer

- The charcoal dryer is an intelligent equipment integrating dehumidification, heating, exhaust temperature and temperature control.

- The unique exhaust heat recovery design can reduce the heat loss of the exhaust, and the overall energy saving is better.

- The charcoal dryer can modulate the temperature and humidity according to the characteristics of the dried material, with a high degree of intelligence.

- There is no need to be supervised during the drying process, and the unit will automatically shut down after the material is dried or the drying temperature is reached.

- The installation and demolition of the charcoal briquette drying machine are very convenient, and it occupies a small area and can be used indoors and outdoors.

Advantages of heat pump charcoal dryer

Traditional coal-fired gas and boiler drying methods are not only time-consuming, high labor costs, but also have potential pollution, safety, and food safety hazards. They will gradually be eliminated when green production is emphasized. The heat pump dryer was born from this, relying on a small amount of electric energy to absorb the heat in the air and transfer it to the drying room. Heat pump dryers are one of the representatives of machinery that utilizes new energy sources and are favored by many environmental protection manufacturers.

The heat pump charcoal drying room can achieve high efficiency and energy saving. It only needs to consume a small amount of electric energy to absorb a large amount of heat in the air, and the power consumption is only 1/4 of that of ordinary electric heating dryers; In addition, compared with coal, oil, and gas dryers, charcoal drying room with a heat pump can save about 60% of operating costs.

Parameters of charcoal briquette drying machine

These are the two most commonly sold models and are heated by wood or coal. The length of each trolley is one meter, the length of the drying room with 8 trolleys is 8 meters, and each trolley can hold 10 trays. For example, the drying box of Model WD-BD 08 is 8 meters long and can hold 8 trolleys with 80 trays.

| Model | WD-BD 08 | WD-BD 010 |

| Drying room size | 8m*2.3m*2.5m | 1mX2.3mX2.5m |

| Circulating fan | 6pcs | 6pcs |

| Dehumidification fan | 2pcs | 2pcs |

| Trolley | 8pcs | 10pcs |

| Tray | 80pcs | 100pcs |

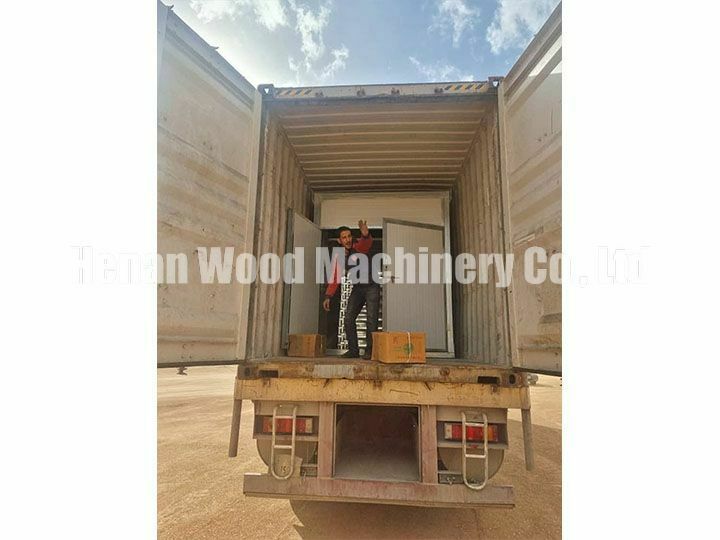

Box-type charcoal dryer shipped to Libya

The Libyan client’s charcoal factory was expanding and producing more and more charcoal briquettes. Natural drying could no longer meet his needs, so he decided to invest in a dryer to improve efficiency.

After learning about the scale of the charcoal plant of the Libyan customer, the sales manager Crystal recommended to him a drying room with a daily output of 3 tons and a length of 10 meters, equipped with 100 pallets. The case of the Libyan client is very successful. The following pictures are the detailed parameters of the dryer purchased by Libyan customers.