Sawdust Briquette Machine | Biomass Briquette Machine for Sale

| Model | WD-WB50 |

| Capacity | 250-350kg per hour |

| Power | 18.5kw/22kw |

| Dimension | 1.7*0.7*1.4m |

| Weight | 700kg |

The Sawdust Briquette Machine can convert waste wood materials, such as sawdust, rice husk, and other biomass, into high-density fuel briquettes. With a capacity of 250–350 kg/h, this machine compresses raw biomass under high temperature and pressure, forming solid fuel rods that are both environmentally friendly and efficient alternatives to traditional fuels like firewood and coal.

The resulting briquettes have a compact form, excellent flammability, and can also be further processed in carbonization furnaces, making them a sustainable choice for energy production. Emphasizing waste utilization, this equipment aligns with ecological goals by repurposing otherwise discarded materials.

Sawdust briquette machine for sale

The biomass briquette machine for sale is versatile, and capable of processing a wide range of raw materials, including various wood wastes and crop residues.

It transforms materials such as sawdust, corn stalks, soybean stalks, and rice husks into sawdust briquettes, promoting sustainable fuel production.

However, before these materials can be processed, two essential steps are required:

Crushing

The raw materials, especially larger particles like branches and stalks, must first be crushed using a wood crusher to achieve the appropriate size.

Drying

The moisture content of the raw materials must be controlled between 8%-12%.

Excess moisture is removed using a dryer before feeding them into the biomass briquette machine.

This preparation ensures the efficiency and quality of the final briquettes produced.

Structure of wood briquettes making machine

The structure of the wood briquettes making machine is designed to enhance performance, efficiency, and ease of use. Key components include.

- Control cabinet. Regulates voltage and temperature; operates the screw propeller in reverse to prevent jamming.

- Motor. High-quality, fast-rotating motor for smooth operation.

- Bearings. Upgraded, thicker bearings enhance wear resistance for stable performance.

- Feeding port. Larger design increases efficiency by allowing more material entry.

- Electric heating circles. Automatically adjusts moisture levels for optimal briquette quality.

- Chopping rack. Collects finished sawdust briquettes after processing.

These components work together to ensure the machine operates efficiently while producing high-quality briquettes.

Sawdust briquette making machine components

- The screw of the biomass briquette machine has undergone multiple debugging processes.

- The pitch has been increased to improve performance.

- The feeding capacity has been enhanced.

- These adjustments have significantly increased the machine’s output.

- The fully automatic control electric heating device is designed for the sawdust briquette machine.

- It can adjust the dryness and humidity of the material.

- This feature ensures stable discharging and forming of the briquettes.

- It also enhances the work efficiency of the sawdust rod-making machine.

- Common molds of the sawdust briquette machine include hexagonal and quadrilateral shapes.

- Special molds can be customized based on customer needs.

- Continuous debugging has led to improvements in the structure of the forming cylinder.

- The modifications reduced friction between the machine and the raw material.

- These adjustments increased the density of the briquettes produced.

Principle of commercial biomass briquette machine

When operating the sawdust briquette machine, requires preheating to 380 degrees Celsius before raw materials can be fed into the machine. Once the desired temperature is reached, the process of briquette formation begins.

Key steps include

- Preheating. The machine must be preheated to 380°C.

- Feeding. After reaching the right temperature, raw materials are placed at the feed port.

- Material movement. The motor drives the bearing and screw conveyor, pushing the material smoothly into the forming tube.

- Extrusion. Under high temperature and pressure, the wood chips or rice husks are extruded through the discharge port, forming the final briquettes.

This process ensures efficient production of dense and uniform briquettes.

Features of sawdust briquette machine final products

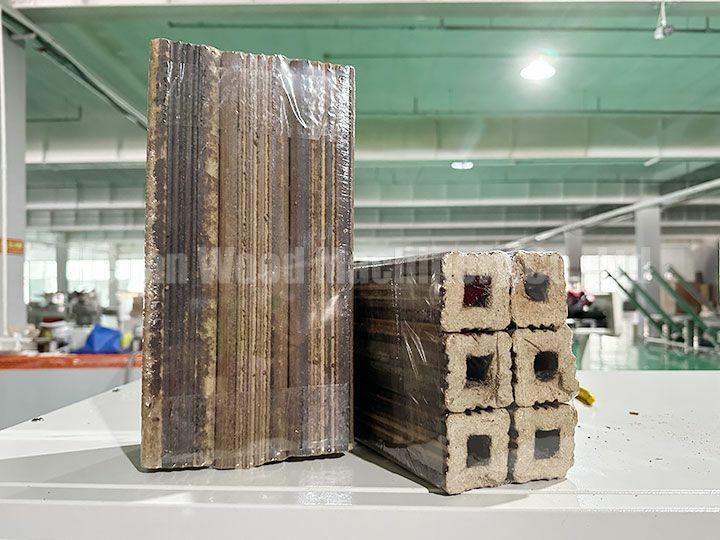

- The common sizes of compressed sawdust briquettes are 40cm or 50cm, with a minimum length of 15cm.

- These briquettes have high density, small size, and good combustibility, making them ideal for replacing firewood and coal, particularly for fireplaces.

- During production, sawdust is compressed under high temperatures and pressure, creating hollow briquettes that help water vapor evaporate.

- Typical outer diameters range from 50-60mm, with apertures of 15-20mm, and shapes include hollow quadrilateral, hexagonal, octagonal, or circular.

- Quality briquettes have no cracks, and a wood-yellow color, and can be optimized through adjustments during production.

Parameters of biomass briquette extruder

| Model | WD-WB50 |

| Capacity | 250-350kg per hour |

| Power | 18.5kw/22kw |

| Dimension | 1.7*0.7*1.4m |

| Weight | 700kg |

How to pack sawdust biomass briquettes?

Our company offers professional briquette packing machines, which can efficiently package sawdust briquettes after they are produced by the biomass briquette machine.

Using a charcoal packing machine, factories can wrap bio-briquettes in customized quantities.

Key benefits of packaging

- Moisture protection. Packaged briquettes are better protected from moisture.

- Ease of transport. Wrapped briquettes are easier to transport.

- Enhanced appearance. The packaging improves the appearance, making the briquettes more appealing to the market.

These features ensure that the packaged sawdust briquettes are not only practical but also market-friendly.

Complete biomass sawdust briquette machine production line

The sawdust briquette machine operates more efficiently as part of a complete biomass briquette production line. This line includes essential equipment such as wood shredders, dryers, and sawdust briquette machines available for sale.

The main steps in the sawdust biomass briquette production process are as follows:

- Initial coarse crushing. Large logs and wood scraps are broken down.

- Fine crushing. The crushed material is further refined into smaller particles.

- Drying. Sawdust is dried to achieve the optimal moisture content.

- Cooling. The dried sawdust is cooled to stabilize it.

- Briquette forming. The sawdust is compressed into briquettes.

- Carbonization. Finally, the briquettes undergo carbonization to enhance their properties.

Various materials, including logs, miscellaneous wood, and furniture leftovers, are transformed into sawdust sticks through this process.

As a professional manufacturer and supplier of biomass charcoal machines, our factory can customize equipment to meet specific needs and provide comprehensive processing solutions to both domestic and international customers at competitive prices.

A complete charcoal plant for sale installed in Guinea

Our company has successfully shipped a complete charcoal production line to Guinea, which includes five sawdust biomass briquette machines as its key components. The charcoal plant in Guinea will produce carbonized biomass briquettes as its final products.

To ensure a smooth setup, we dispatched one of our engineers to Guinea to assist with the installation of the entire production line. The customer has now completed the installation process and has begun producing charcoal briquettes.

Can bark and leaves be used to make sawdust biomass briquettes?

After purchasing a sawdust briquette machine, it’s essential for customers to evaluate the suitability of their raw materials for producing charcoal briquettes.

An Indonesian customer reached out to us during their purchase process, expressing concerns about the materials available near their factory. They noted that numerous trees surrounded their facility, and many pruned branches and leaves were typically burned.

From an environmental protection perspective, they inquired whether they could use these leaves or barks for charcoal production. The good news is that a variety of raw materials are suitable for making charcoal, including:

- Sawdust

- Corn stalks

- Leaves

- Barks

However, it’s important to note that while leaves and barks can be used, they should be combined with other materials, such as sawdust, to achieve optimal results in the biomass briquette production process.

Global cases of biomass briquette machines for business

We recently completed the shipment of a complete biomass briquette production line to Myanmar for a client engaged in the charcoal business. This businessman operates his own charcoal processing factory locally and discovered our charcoal machine channel on YouTube while searching for equipment suppliers.

After thorough discussions with our sales manager, the client opted for a comprehensive package that included:

- Sawdust briquette machine

- Wood crushers

- Carbonization furnace

- Related auxiliary equipment

Our biomass briquette machines have been successfully implemented in various countries, aiding charcoal plants and wood processing facilities in producing sawdust biomass briquettes profitably.

If you’re interested in similar solutions, feel free to reach out to us at any time for consultation.

Invest in Shuliy’s wood briquette extruder

In conclusion, our advanced wood briquette extruder is designed to efficiently convert wood waste into a sustainable fuel source. This environmentally friendly solution not only supports wood processing but also helps you achieve your sustainability goals.

If you’re looking to transform wood waste into a valuable resource, our company is your ideal partner. Contact us today to discover innovative solutions tailored to your production needs.