Coal Briquette Processing Plant | Coal Making Machine

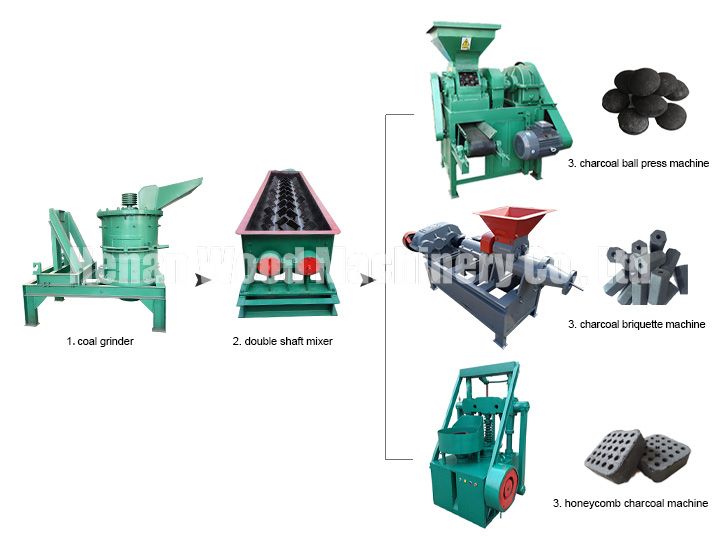

The rapid development of the mechanization of coal mining has created a space for us to develop coal briquette processing plant. Briquette equipment is the preferred investment project for energy conservation and emission reduction in the coal industry. Fine coal powder is not easy to transport and use as fuel, so the coal powder is usually pressed into shapes of balls, squares, honeycomb, and other block shapes through coal briquette equipment.

Application of compressed coal briquette production line

The coal briquette production line can press the coal slime, coal ash and other loose coal products dried to a certain degree into briquette, briquette and various carbon products, which can be directly smelted and applied; at the same time, it can also achieve the forming and various types of iron powder. The molding of the mineral powder. The equipment has been widely used in metallurgy, mining, coal, refractory materials, abrasives, fertilizers, ceramics and other industries.

What are the main steps of coal briquette processing plant?

shredding–mixing–pressing and forming–drying–packing

- Shredding. Put the raw materials into the coal pulverizer, and the pulverized coal is about 8mm in diameter. Unlike charcoal, coal does not need to be pulverized particularly finely when processing coal. Usually, it is pulverized into about 8 mm in coal powder with a coal pulverizer.

- Mixing. In this step, mix pulverized coal powder, binder and water together. Put those three ingredients into a double-shaft mixer in a certain proportion to mix.

- Pressing and forming. Briquetting is the most important step of the coal briquette processing plant. WOOD machinery has three different coal making machines, including charcoal briquette making machine, honeycomb coal maker and charcoal ball press machine.

- Drying. The prepared coals need to be dried for excess water, the size of our drying equipment can be customized by customers’ demand.

- Packing. Packing is for better transportation. WOOD machinery provide professional coal packing machines to save customers the trouble of fragile coal and difficult to transport.

Main equipment of coal briquette processing plant

Coal pulverizer

The compound coal crusher is mainly used in coal plants, coal mines, power plants, and other factories that process coal. It is a new type of crushing equipment that is suitable for crushing and processing materials with higher moisture and viscosity. The output particle size of the compound crusher can be adjusted arbitrarily, its crushing ratio is large, and the crushing efficiency is high.

Double-shaft mixer

This mixer is very suitable for stirring coal powder. Because the raw materials need to be prepared in advance, water and binders are added to the fine grounded coal powder. Put all materials in the mixer and it will stir them very evenly.

Coal making machine

The coal briquette machine will extrude the mixed pulverized coal into coal rods through high pressure. We have a variety of different molds to make coal briquettes of different shapes. Because the machine works continuously, we have prepared a variety of cutting equipment.

Honeycomb coal briquette machine

Honeycomb coal briquette machine is also one of the machines used for pulverized coal forming. The honeycomb coal briquette machine can easily exchange molds. The functions of the briquettes machine can be greatly expanded by replacing the molds of different shapes, which are very popular among users.

Coal ball press machine

The charcoal ball press machine is forming equipment that presses powdered materials into different shapes. The most common shaps of molds are pillow-type, bar-type, round and so on. WOOD machinery can provide customized type according to your demand. We can also make lettering charcoal balls with special molds.

Drying equipment

The coal drying room is the most commonly used machine for drying coal, suitable for drying coal balls, coal sticks, coal honeycomb briquettes, etc. WOOD machinery also provides mesh belt dryers, which are suitable for drying briquettes with relatively high hardness. The moisture content of the finished product after drying is about 3%-5%.

Coal briquette packing machine

If customers want to pack briquettes and briquettes, we have professional packaging machines that can choose different packaging methods according to customer needs.

Advantages of coal briquette processing plant

- This production line produces clean coal with a high degree of automation, which is more efficient than traditional hand-made coal and saves costs.

- Clean coal is environmentally friendly, can reduce exhaust emissions, and is an important measure to protect the environment.

- The machines in the production line can be matched according to the needs of customers. Among them, there are various types of coal briquette forming machines, which can make coal blocks of different shapes. Therefore, this production line is very popular with customers.

Coal briquette production line exported to Romania

Recently, we exported a whole production line for producing coal briquettes to Romania. A customer from Romania saw a video of our charcoal machine on YouTube, he clicked to visit our channel and was delighted to see the machine he wanted. After communicating with the customer, we confirmed the demand: the customer needs a WD-BP430 machine and related equipment. The customer has a coal processing plant in Romania, which has always been producing briquettes. our sales manager configured him a production line, including a coal pulverizer, twin shaft mixers, a coal briquette machine, a packaging machine and conveying devices.

Sales service of coal briquette production line

- Pre-sales service: Provide you project planning, process design, and develop a set of equipment that suits you; design and manufacture the coal briquette production line according to your special needs, and provide training for your technical operation.

- In-sale service: Precise production equipment, and accompany our customer to complete the acceptance of the equipment, assist in the preparation of the installation plan, and detailed process.

- Our company will be sent technicians to customers’ site to guide the installation of equipment, commissioning the coal briquette makinfg machine to normal production, and training the operators for use and maintenance.