Barbecue Charcoal Production Line | BBQ Charcoal Briquette Project

| Continuous carbonization furnace | Model: SL-800 Dimension: 9*2.6*2.9m Power: 22kw Capacity: 300-400 kg/h |

| Charcoal crusher machine | Model: SL-C-600 Power: 22kw Dimension: 3600*1700*1400mm Capacity:500-600kg/h |

| Wheel grinder machine | Model: SL-W-1300 Power: 5.5kw Capacity: 300-500kg/h |

| Charcoal ball press machine | Power: 5.5kw Capacity: 1-2 t/h Weight: 720kg |

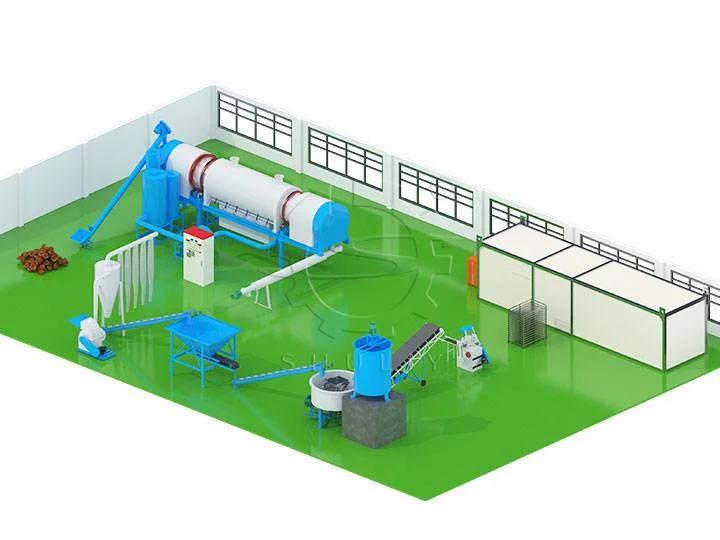

The Barbecue Charcoal Production Line is a complete and professional solution for producing high-quality charcoal briquettes. It supports multiple briquette shapes, including ball, pillow, bread, and oval types, allowing manufacturers to meet different market demands. This production line serves as an efficient alternative to traditional biomass fuels and raw coal, contributing to energy conservation and reduced emissions.

Equipped with advanced technology, the Barbecue Charcoal Production Line integrates key machines such as carbonization furnaces, crushers, mixers, briquette forming machines, dryers, and packaging systems. Automated conveying and storage systems further improve workflow efficiency while significantly lowering labor requirements.

With a flexible output capacity ranging from 300 kg/h to 2000 kg/h, the Barbecue Charcoal Production Line can be customized to suit different production scales. This makes it an ideal choice for charcoal and coal processing plants seeking higher productivity, stable operation, and long-term profitability.

BBQ charcoal briquette machine raw materials

Before delving into the intricacies of production, understanding the diverse raw materials used in BBQ charcoal briquette projects lays the foundation for efficient and sustainable manufacturing.

The common materials of barbecue charcoal are bamboo, fruitwood, coconut shells, nutshells, and so on. They are all totally natural and healthy. The above materials are very easy to collect and the cost is also low, therefore, the barbecue charcoal production line is a profitable project and environmentally friendly.

The main equipment of the barbecue charcoal production line

With raw materials identified, exploring the essential equipment of the barbecue charcoal production line becomes crucial. These machines are pivotal in transforming raw materials into finished briquettes.

| No. | Machine’s name |

| 1 | continuous carbonization furnace |

| 2 | wood hammer mill |

| 3 | charcoal grinder mixer |

| 4 | charcoal ball press machine |

| 5 | continuous dryer |

| 6 | barbecue briquette packing machine |

BBQ charcoal production line main steps

Now equipped with knowledge of the equipment, let’s outline the step-by-step process involved in producing high-quality BBQ charcoal briquettes, ensuring clarity from carbonization to packaging.

Step 1: Carbonizing

The raw materials like logs, branches, or coconut shells will be sent to the hoist carbonization furnace first.

If your materials are rice husks, wood chips, or any other materials of small size, a continuous carbonization furnace is definitely a good choice. The furnace will turn them into charcoal at a high temperature.

Step 2: Crushing

A charcoal crusher will crush the processed charcoal into small powder. The finely grounded powder is about 1 mm.

Step 3: Mixing and pressing

In the process of making barbecue charcoal, appropriate water, and binders should be added. The charcoal grinder mixer will stir and then pre-press them to make them fully mixed and expel some air.

Step 4: Making BBQ charcoal briquettes

There are three choices you can choose, from charcoal briquette machine, charcoal ball press machine, and honeycomb charcoal machine. Each of them has different features and products. Put the pre-processed carbon powder into different machines.

Step 5: Drying

The molding process of various types of charcoal briquettes requires the addition of a certain proportion of binder and water. Therefore, the freshly produced biomass-based charcoal briquettes have higher moisture content and need to be dried to improve various strength indicators.

Shuliy Machinery provides two charcoal dryers: mesh belt dryer and drying room.

Step 6: Packing

A quantitative packing machine is used to wrap charcoal balls. The sealing and cutting machine is used to pack honeycomb charcoal and charcoal briquettes.

Parameters of barbecue charcoal production line

| Item | Specifications |

| Continuous carbonization furnace | Model: SL-800 Dimension: 9*2.6*2.9m Power: 22kw Capacity: 300-400kg/h Weight: 9ton Machine shell thickness(steel): 11mm |

| Charcoal crusher machine | Model: SL-C-600 Power: 22kw Dimension: 3600*1700*1400mm Capacity:500-600kg/h Final size: less than 5mm |

| Wheel grinder machine | Model: SL-W-1300 Power: 5.5kw Capacity: 300-500kg/h Inner diameter:1300mm |

| Binder mixer | Model: SL-M800 Input capacity: 0.6m³ Power: 3kw Inner diameter: 800mm |

| Charcoal ball press machine | Power: 5.5kw Capacity: 1-2t/h Pressure: 50tons per time Weight: 720kg |

| Packing machine | Packing weight: 20-50kg per bag Packing speed: 300-400 bags per hour Power: 1.7kw Dimension: 3000*1150*2550mm |

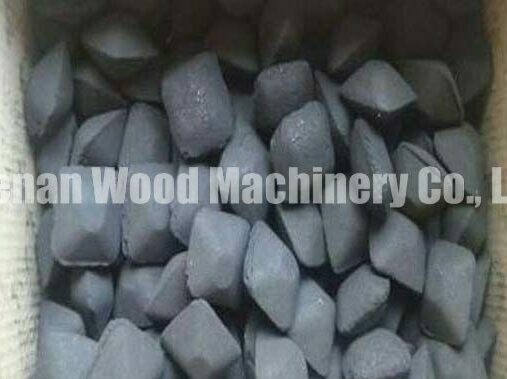

BBQ charcoal briquettes display

After introducing the main steps in the BBQ charcoal production line, let’s take a look at the display of finished BBQ charcoal briquettes, showcasing the quality and variety that our production line can achieve.

Barbecue charcoal production line machines in stock

Our charcoal machines are fully stocked and can be customized according to the special needs of customers.

What are the advantages of the BBQ charcoal briquette project?

After reviewing the barbecue charcoal production line machines in stock, let’s explore the advantages of the BBQ charcoal briquette project to better understand why investing in this project is a wise choice.

- Charcoal briquettes are made from 100% natural raw materials such as wood or bamboo, with no additives or chemicals.

- High-density BBQ charcoal with high calorific value, no sparks, and long burning time.

- Produces little ash after burning, making grill cleaning easy.

- Suitable for both commercial barbecue use and home use.

- BBQ charcoal production line machines are in stock and can be flexibly configured.

- Compact production line layout, ideal for small and medium charcoal processing plants.

Having discussed the advantages of the BBQ charcoal briquette project, let’s now look at the prospects of the barbecue charcoal production line to see its potential for future growth and success.

Prospects of the barbecue charcoal production line

With the deterioration of the environment, more and more countries have begun to use charcoal instead of coal. At the same time, the use of charcoal is indispensable for barbecue in summer, heating in winter, and indoor deodorization. The demand for pressed charcoal has given birth to the development of charcoal products.

From industrial burning high-temperature charcoal to activated carbon for water treatment in water plants, indoor deodorizing coconut shell activated carbon, to charcoal for heating in our lives, barbecue charcoal, etc., it is precisely these users’ needs. The charcoal industry will have very good prospects in the future.

Conclusion

Shuliy’s barbecue charcoal production line can not only provide you with diversified charcoal pellet and charcoal brick production solutions but also become the first choice for modern coal processing plants with its energy-saving and emission-reducing characteristics. Our equipment integrates advanced technology to ensure maximum production efficiency and product quality.

Contact us now to discuss how to improve your production efficiency and competitiveness through the Shuliy brand barbecue charcoal production line!