Horizontal Carbonization Furnace | Hardwood Charcoal Furnace

| Model | WD-HC1900 |

| Capacity | 2500-3000kg/12-14h |

| Weight | 5500kg |

| Size | 5*2.3*2.5m |

A horizontal carbonization furnace is carbonization equipment for processing charcoal, which can carbonize a variety of raw materials, such as bamboo, logs, biomass sticks made by the sawdust briquette machine, coconut shells and other relatively large materials. Because it is internally heated, the combustible gas generated after burning wood uses these gases. The combustion completes the carbonization of the material. In addition, it is equipped with smoke purification equipment to reduce waste smoke emissions.

Application of biomass carbonization furnace

A horizontal carbonization furnace is a kind of biomass carbonization furnace, which is used to carbonize biomass materials like branches, woodblocks, bamboo, coconut shell blocks, scrap pieces in furniture factories, etc. The material can be directly carbonized, or it can be crushed with a wood chipper or a wood crusher first, and then carbonized after being made into biological wood sticks with a sawdust briquette machine.

Raw materials of horizontal carbonization furnace

Horizontal carbonizing machines and other types of carbonization furnaces, such as continuous carbonization furnaces and vertical carbonization furnaces, are important equipment for the production of charcoal. Charcoal processing plants can choose their own carbonization machine according to their raw materials and output.

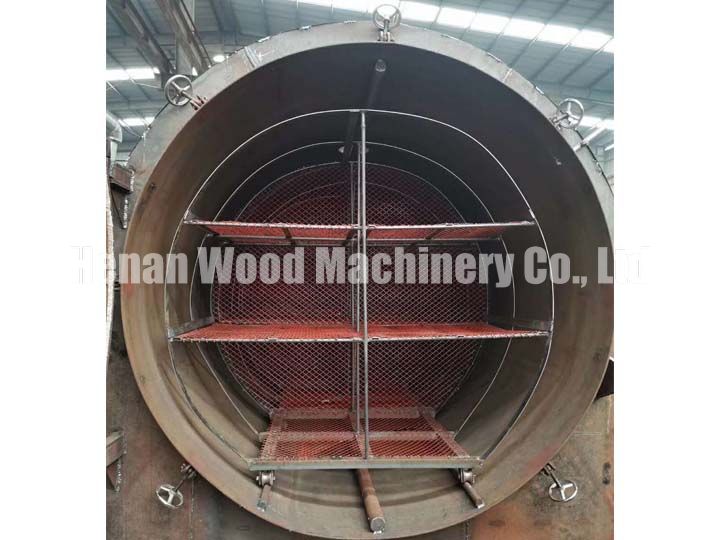

Horizontal bamboo carbonization furnace products

Features of horizontal carbonization furnace

1. Carbonizing stove is equipped with insulation materials

The horizontal bamboo carbonization stove adopts a horizontal manufacturing process with a double-layer structure inside. There is a lightweight high-temperature insulation material in the middle of the interlayer, which can always keep the temperature in the furnace from dissipating.

2. Horizontal carbonization furnace has good sealing

The furnace door is sealed with high-temperature rock wool from the boiler packing, no air will enter, and the charcoal output rate is much higher than that of the conventional carbonization furnace.

3. Hardwood biomass charcoal furnace saves fuel

During the carbonization of materials, a lot of light yellow combustible gas will be produced. These gases can be diverted to the combustion zone of the carbonization furnace through the pipes of the carbonizaing stoves for secondary ignition and heating, which is more environmentally friendly and saves fuel.

4. Convenient feeding and unloading

The horizontal carbonizing furnace is equipped with rails and carts, which can make full use of the space in the furnace, which is more convenient to use and reduces the labor intensity of workers.

Operating instructions of horizontal charcoal making machine

First, find a flat piece of land and place the horizontal carbonizing machines. Open the furnace door and put in the raw materials that need carbonization. Fill the furnace as much as possible. In the next step, use wood to start the fire. When the temperature gauge in the hardwood charcoal furnace rises to 150-200 degrees, the horizontal log charcoal stove will be discharged. Combustible gas, gas will ignite spontaneously after passing through the pipeline; after 5 hours of the carbonization process, the internal combustible gas is gradually used up, and the flame will become smaller and smaller at this time. At the same time as the fire is extinguished, the carbonization is completed.

After that, the carbonization furnace cannot be opened directly, because the temperature of the carbonization raw materials in the furnace is too high and it is easy to ignite spontaneously and cause danger.

You should use the furnace’s own spray system to properly pour some water, or wait until the temperature of the furnace surface drops below 50 degrees, then the furnace door can be opened.

Horizontal charcoal making machine video

Parameters of hardwood charcoal furnace

| Type | Capacity | Weight | Size |

| WD-HC1300 | 900-1200kg/12-14h | 2500kg | 3*1.7*2.2m |

| WD-HC1500 | 1500-2000kg/12-14h | 4000kg | 4.5*1.9*2.3m |

| WD-HC1900 | 2500-3000kg/12-14h | 5500kg | 5*2.3*2.5m |

A horizontal charcoal making machine needs 12-14 hours to carbonize materials, the specific carbonization time will have some deviation because of different raw materials.

Further processing of horizontal carbonizing furnace product

After carbonizing various raw materials, many customers choose to further process the charcoal. For example, first, pulverize the charcoal into fine charcoal powder, add a binder and stir evenly, then use professional machines to make barbecue charcoal balls or hookah charcoal. Wood machinery designed and provided several complete charcoal production lines, our sales manager will recommend related machines according to your demand.

Loading and delivery of horizontal charcoal making machine