How to stop wood from cracking?

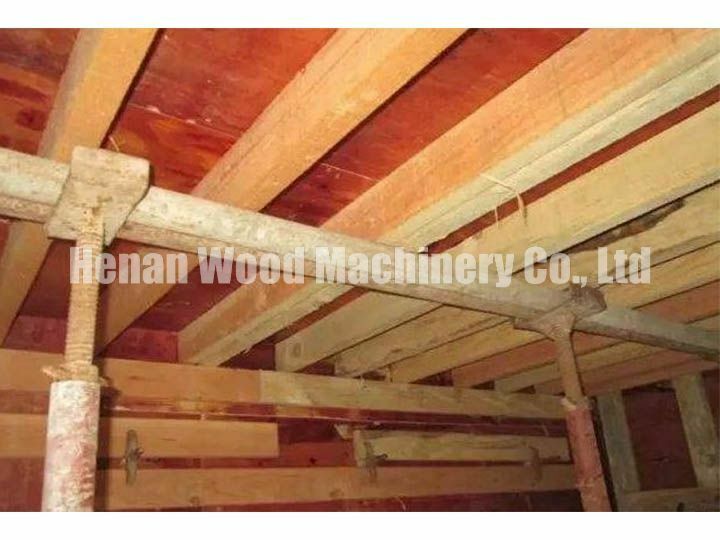

We know that building wood is a kind of high-quality wood, which has been processed by domestic multi-blade saws to become wood of fixed specifications and dimensions. In the production of furniture, building wood is often used as the backbone of many furniture and plays a supporting role. At the same time, building wood usually plays the role of earthquake-resistant reinforcement in civil construction in life, so in life, building wood plays a very important role in civil engineering.

However, wood will have certain properties of thermal expansion and contraction, so cracking of building wood is a relatively common phenomenon. Cracked wood is not suitable for re-use as furniture. If the wood with serious cracks cannot be used for furniture, one of the good choices is to use a shaving machine to make shavings, or pulverize the wood into sawdust. So how can we prevent the cracking of building wood?

Before purchasing

Before purchasing building wood, we need to communicate with the manufacturer to understand the physical properties of building wood. Is it easy to crack? How many knots are there? How does it look? These need to be determined first.

Storage of wood

When we store building wood, we need to avoid direct sunlight, otherwise, it will lead to excessive stability, which will damage the plant fiber structure inside the building, resulting in a reduction in the moisture content of the building and cracking.

Humidity in the air is the key point when storing wood. It is recommended to use an air humidifier when necessary. Some experienced wood processing factories have said that it is very good to have an air humidifier indoors, and the humidity is required to be controlled at about 50%.

Timber in stock should be inspected regularly, and those that are deformed, cracked, bug-bitten, and corroded should be picked out during inspection.

When storing wood panels, they must be installed and operated in the correct way. If the operation is not in place, the product will be deformed. Here, it should be noted that when laying wood products, special attention should be paid to leaving appropriate gaps, and there should be about 2 mm around the panels. The expansion joints can prevent damage to the wood in the future and affect the service life of the product.