Newest Charcoal Making Machine | Coconut Shell Carbonization Furnace

| Model | WD-1320 |

| Hourly Feeding Capacity | 2.5-3Tons |

| Working method | continuous carbonizing |

| Reactor Size | 1700mm |

| Total Power | 72kw/h |

| Floor Area (L*W*H) | 50*15*10m |

The newest charcoal making machine is also called the coconut shell carbonization furnace, which is a new environmentally friendly carbonization furnace launched by WOOD machinery. The newest charcoal making machine adopts a modular design, which is easy for installation and maintenance. Advanced automation technology and precise temperature control can deal with a wide range of raw materials. It truly realizes the multi-purpose use of one machine, which can be used to carbonize biomass such as coconut shells, sawdust and straw. , and can also carbonize sludge and domestic waste.

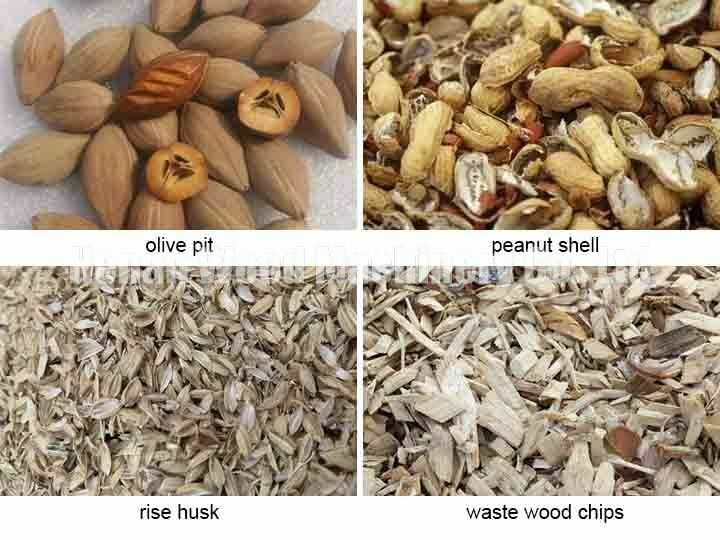

Raw materials of newest charcoal making machine

The new carbonization furnace can deal with various waste biomass, such as straws, rice husks, sawdust, bark, branches, coconut shells, walnut shells, palm shells, peanut shells, date pits, fruit peels, beef bones, coffee grounds, olive pits, etc.

The continuous charcoal machine can not only carbonize our common coconut shells or sawdust but also carbonize almost all biomass waste and sludge. For example, domestic waste, paper mill waste, river sludge, industrial sludge, etc. Carbonizing garbage is more environmentally friendly than traditional combustion, which can reduce the volume of garbage, reduce environmental pollution and save energy.

The charcoal making machine can also carbonize chemical substances, such as activated coke, magnesium oxide, sodium oxide, etc.

Carbonization effect of charcoal making machine

Working principle of charcoal making machine

Crushing and drying

Materials larger than 20mm need to be crushed first. In addition, materials with moisture higher than 25% need to be dried with drying equipment, such as fresh coconut shells or bamboos, which generally have a larger moisture content.

Carbonization

The main carbonization furnace is preheated, and then the dried material is conveyed to the feeder by the conveyor belt, and then enters the main carbonization furnace for carbonization. If the raw material is coconut shell or other fruit shells, it can be discharged through the water cooling system after carbonization for 18-20 minutes.

Generate flammable gas

After about 20 minutes of feeding, combustible gas is generated, which first enters the cyclone dust removal system for cleaning, and then enters the condenser to be separated into wood vinegar and tar. The remaining gas is drawn to the outside of the main furnace by the induced draft fan and heated.

Utilize and treat waste gas

A part of the waste heat flue gas can be used to heat the dryer, and the remaining flue gas is discharged through water cleaning and water spraying and other dust removal systems.

Advantages of coconut shell carbonization furnace

- The flue gas generated by the machine during the carbonization process is treated by multiple dust removal devices to meet the standard emission requirements.

- Although the temperature of carbonization is several hundred degrees, the temperature of the casing is below 35℃, which can ensure the safety of workers and the working environment.

- The combustion chamber of newest charcoal making machine is designed with ceramic fiber, which has good thermal insulation effect and has a service life of up to 12 years, avoiding secondary pollution of castables.

- The carbonization furnace has a high degree of automation, and uses intelligent equipment control and frequency conversion technology to adjust the temperature to make the machine more energy-saving

- The continuous carbonization furnace adopts a double furnace design to form a multi-stage thermal structure, the inner cylinder is preheated and dried, and the thermal efficiency is higher, making the carbon making machine more energy-saving;

Charcoal making machine parameters

| Model | WD-0812 | WD-1015 | WD-1218 | WD-1320 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | continuous carbonizing | |||

| Reactor Size | 800mm | 1000mm | 1300mm | 1700mm |

| Heating Materials | Charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc. | |||

| Total Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Cooling Method | Recycling Water Cooling |

The heating methods are various, including charcoal, wood, diesel, natural gas, LPG, biomass pellets, etc.. Customers should pay attention to the area occupied by carbonization furnace, the smallest one will take 35*15*7m.

Loading and delivery of newest carbonization furnace

Malaysia is rich in natural resources and there are many trees. In order to make full use of waste wood, the local wood processing factory purchased our carbonization furnace for carbonization palm husks and lumber are sold directly for additional profit.

They chose the WD-1015 charcoal making machine, which can produce 0.8-1 tons each hour. After they received the carbonization furnace, they began their own charcoal business.