Charcoal Briquette Packing Machine | Hookah Coal Packaging Machine

| Model | WD-SP |

| Voltage | 220V/50-60HZ, 2.2KW |

| capacity | 0-30pcs/min |

| Sealing temperature | 140℃-180℃ |

| Thickness of film | 0.015-0.1mm |

The charcoal briquette packing machine is mainly used for the packaging of charcoal, hookah charcoal, ignition charcoal, barbecue charcoal, biomass rods, clean coal, and other products. After packaging, the appearance is exquisite and beautiful, convenient for storage and transportation, and quick and convenient to use. WOOD Machinery has a mature automatic packaging project. The automatic packaging machine packs speed blocks and has high work efficiency. Just tell us the raw materials you want to pack, and we can tailor suitable charcoal or hookah charcoal packaging solution for you.

Brief introduction of charcoal briquette packing machine

WOOD machinery is committed to providing customers with the highest quality charcoal packaging machines. In order to meet the needs of users, we produce three types of charcoal packaging machines, including hookah charcoal packaging machines, quantitative packaging machines, and shrink packing machines. Customers can choose different charcoal briquette packing machine according to their raw materials.

Shisha charcoal packing machine

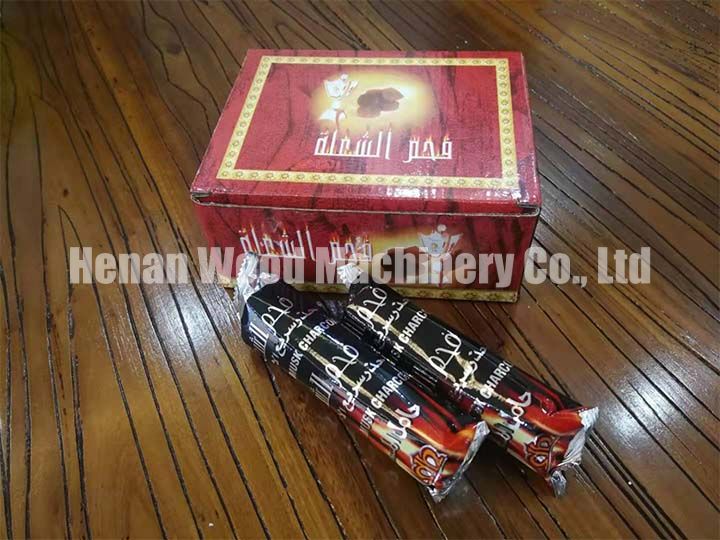

Packing round shisha charcoal

Hookah briquettes made by a shisha charcoal machine can be well wrapped in this step.

Structural characteristics of charcoal briquette packing machine

- This charcoal briquette packaging machine adopts touch screen control, main control circuit adopts intelligent chip, accurate measurement, convenient and quick parameter setting, simple operation and convenient adjustment.

- The fault self-diagnosis function, the fault display is clear at a glance.

- Digitally input the sealing and cutting position to make the sealing and cutting position more accurate.

- Independent PID control of temperature, better suitable for various packaging materials.

- The transmission system is simple, easy to maintain, less wear and long life.

- The sealing performance is good, the packaging effect is beautiful, and the production date, inflation, and three-dimensional folding angle can be printed simultaneously.

More details of hookah packing machine

The conveyor belt is very wide and the conveying speed is adjustable, which can continuously convey a large amount of hookah charcoal, which greatly saves labor costs while ensuring the complete shape of the hookah charcoal.

The material distribution equipment divides the hookah charcoal sent by the conveyor belt into groups, the quantity of each group is generally 10, and the quantity can also be customized.

The distribution device can quickly and accurately group the carbon blocks, which improves packaging efficiency.

Use the bilingual screen to easily set parameters and functions, and use the multi-link film reel to pull smoothly.

Video of packing round shisha charcoal

Parameters of charcoal briquette packing machine

| Type | WD-HP 280 | Remark |

| Packaging film width | 100-280mm | |

| Bag length | 80-300mm | |

| Packing height | 5-60mm | Above 60mm can be customized according to customer requirements |

| Film roll diameter | ≤320mm | |

| Capacity | 120 bags/min | |

| Power | 220V50HZ 3.55kw | |

| Size | (L)4000×(W)900×(H)1500mm | |

| Weight | 500kg |

Video of packaging cube-shaped hookah charcoal

Packing cubic shisha charcoal is a little different from packing round ones, if you are interested, welcome to consult us and leave your comments and demands at the bottom of the page. Our sales manager will send you related details.

Quantitative BBQ charcoal packing machine

Introduction of charcoal briquette packing machine

A quantitative packaging machine is used to package barbecue briquettes made by a BBQ charcoal press machine. It is mainly composed of four parts: automatic weighing device, conveying device, sewing device and computer control. The charcoal briquette packing machine is suitable for automatic quantitative packaging of various types of carbon, briquette, biological particles, granular materials (feed, quartz sand), organic fertilizers, powder particles, mixed materials, flake materials and irregular materials. It has the characteristics of reasonable structure, beautiful appearance, stable operation, energy-saving and electricity saving, convenient operation and accurate weighing.

Features of BBQ charcoal briquette packing machine

- Using carbon steel production process.

- The equipment adopts a bucket weighing, independent suspension sensor, and a frequency converter to control the motor speed, and the signal transmission is stable to ensure the weighing speed.

- Belt feeding, no extrusion damage to the material.

- The main machine adopts fast, medium and slow three-speed feeding to ensure the accuracy and speed of measurement.

How to adjust the weight of product?

- Turn on the machine.

- Set target data,then click “confirm”.

- Set lead(Packaging slows down at the end).

- Long press “revise”,hang a weight with a known weight ,enter the weight and confirm.

Parameters of BBQ charcoal briquette packing machine

| Model | WD-BP |

| Packing weight | 20-50 kg/bag |

| Packing speed | 300-400 bags/h |

| Power | 1.7kw |

| Dimension | 3000*1150*2550mm |

Shrink packaging machine

Introduction of shrink packing machine

The sealing and cutting machine is a fully automatic unmanned packaging machine, which is widely used in mass production and packaging, with high work efficiency, automatic film feeding and punching, and automatic film sealing and cutting. It can be used with an automatic charcoal briquette production line or coal briquette processing plant. It is the first choice for charcoal sealing and heat shrink packaging.

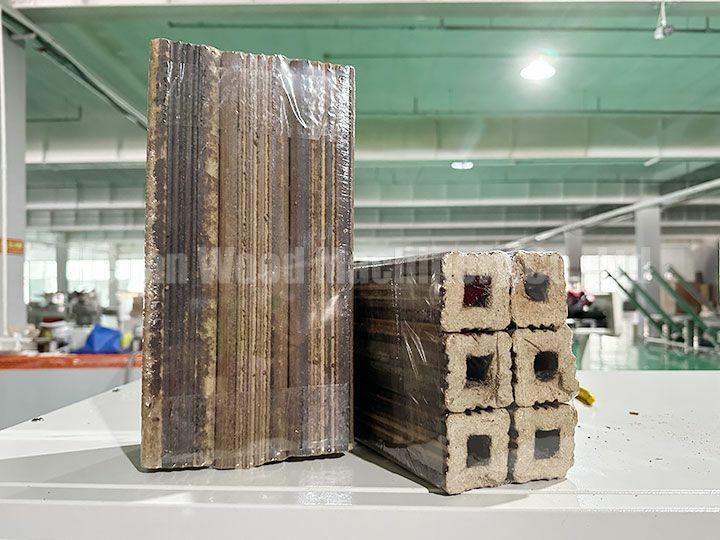

Packing effect of charcoal briquette packing machine

Working video of charcoal briquette packing machine

Features of shrink packing machine

- The packaging machine has a high degree of automation and is easy to operate, only need to set parameters on the control panel.

- The packaged finished product has a flat seal and is widely used, and can be used to package food, beverages, honeycomb, daily necessities, electronic products, etc.

- There is a special place under the machine to recycle the excess film that is cut to ensure that the workshop is clean.

Shrink charcoal briquette packing machine parameters

| Model | WD-SP |

| Voltage | 220V/50-60HZ, 2.2KW |

| Packing capacity | 0-30pcs/min |

| Max. Sealer size | L+2H≤550mm, W+H≤35mm, H≤140mm |

| Sealing temperature | 140℃-180℃ |

| Thickness of film | 0.015-0.1mm |

| Shrink film | POF, PVC, PE |

| Machine size | 1760*900*1580mm |