Compound Coal Crusher | Vertical Coal Pulverizer

| Model | WD-CC800 |

| Wheel diameter(mm) | 650 |

| Height of cylinder (mm) | 800 |

| Spindle speed (r/min) | 1350 |

| raw material size (mm) | 50 |

| Discharge size (mm) | 0-5 |

| Processing capacity (t/h) | 5-15 |

| Motor Power (kw) | 30 |

| Weight (t) | 2.3 |

The compound coal crusher is also known as the vertical coal pulverizer. The coal crusher is a new type of industrial equipment launched in response to the current situation of the coal plant. Its high efficiency and low consumption are its outstanding characteristics. The fuselage is made of wear-resistant materials with long service life and a wide range of crushing materials, such as coal, coal gangue, slag, and other materials, which are favored by many manufacturers.

Brief introduction of the vertical coal pulverizer

The compound coal crusher is mainly used in coal plants, coal mines, power plants, and other factories that process coal. It is a new type of crushing equipment that is suitable for crushing and processing materials with higher moisture and viscosity. The vertical pulverizer can crush coal, ore, rock, or other medium-hard materials that are dry or contain less than 20% moisture. The coal crusher is simple in structure and easy to operate. The crushed coal powder can either be put into a honeycomb briquette machine for forming, or a briquette machine can be used to make briquettes.

Application of compound coal crusher

Its performance has reached the domestic advanced level, used for crushing various medium-hard ore, and can be widely used in mining, metallurgy, refractory, cement, coal, glass, ceramics, electric power, and other industries. Its compressive strength does not exceed 140 MPa and the humidity does not exceed 15%. In the coal briquette production line, WOOD machinery equips with coal pulverizers to crush coal.

Advantages of vertical coal pulverizer

- The output particle size of the compound crusher can be adjusted arbitrarily, its crushing ratio is large, and the crushing efficiency is high.

- The material after the coal crusher has high moisture content, so the material with large mud content should not be blocked.

- The wearing parts of the compound coal crusher are made of high hardness, high toughness, multi-element alloy materials, the machine is wear-resistant, and the service life is increased by 2-3 times.

- Energy consumption and power consumption of the vertical coal pulveriser are very low, production efficiency is high, energy saving, and the total production cost is ultra-low.

Technical parameters of compound coal pulverizer

| Type | WD-CC800 | WD-CC1000 | WD-CC1250 | WD-CC1500 | WD-CC1750 |

| Wheel diameter (mm) | 650 | 800 | 1000 | 1250 | 1560 |

| Height of cylinder (mm) | 800 | 850 | 850 | 1000 | 1410 |

| Spindle speed (r/min) | 1350 | 970 | 740 | 650 | 600 |

| raw material size (mm) | 50 | 70 | 100 | 100 | 100 |

| Discharge size (mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| Processing capacity (t/h) | 5-15 | 10-30 | 20-60 | 30-80 | 40-100 |

| Motor Power (kw) | 30 | 50 | 75 | 110 | 132 |

| Weight (t) | 2.3 | 4.5 | 9.73 | 18.1 | 26.61 |

Generally speaking, the smaller size is more popular for its good price. But the large coal plant prefers to WD-CC1500 for its large capacity.

Coal pulverizer application in coal briquette production line

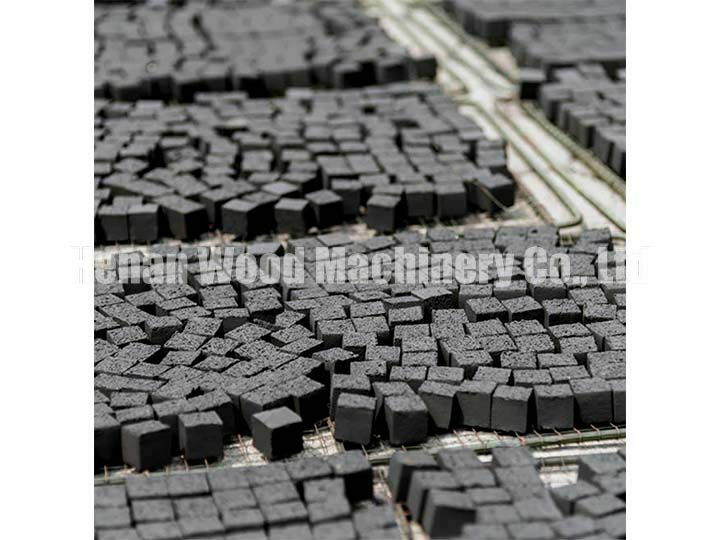

The raw material of the coal briquettes production line is finely grounded coal powder. So the first step of the production is to use a compound coal crusher to shred coal. Before forming, the pulverized coal needs to be mixed with the binder and water according to a certain ratio, which can increase the viscosity of the briquettes and help the pulverized coal to form better.

The related equipment of the compound coal crusher includes coal ball press machine and honeycomb briquette press machine.

The coal ball press machine is an important forming machine for coal powder, which can press them into different shapes, including round, pillow, square, and so on.

It uses two rollers to press the prepared pulverized coal powder and produces high-density coal briquettes by high pressure. This machine is widely used in the coal industry and metallurgical industry.

Honeycomb coal briquette machine is a briquette machine equipment that presses coal powder. Various shapes can be made, which mainly include hexagon and honeycomb shapes.

Difference between charcoal hammer mill and coal crusher

The capacity of the compound coal crusher is larger than that of the hammer mill, the price is lower, which is more suitable for factories with a low budget. But if it is used to crush charcoal, the effect is not as good as that of the hammer mill. Therefore, for crushing charcoal, we recommend customers use a hammer mill, which can crush the charcoal very finely and reach the standard of making hookah charcoal.