Wood Crusher Machine for Sale | Waste Wood Shredder

| Brand | Shuliy Machinery |

| Parameter | 300-4000kg/h |

| Power method | Electric motors and diesel engines |

| Customize service | Inlet design, movement method |

| Dhamana | miezi 12 |

The Wood Crusher Machine can produce sawdust from various raw materials, including wood, branches, and bamboo. Designed to handle a range of materials such as pine, fir, and corn stalks, this machine transforms them into high-quality sawdust.

With a capacity ranging from 300 to 4000 kg/h, it offers impressive productivity while maintaining low energy consumption. The equipment is not only easy to install and operate but also requires minimal maintenance, making it a cost-effective solution for businesses.

This sawdust can be further processed into products like charcoal, plywood, and paper. If you’re interested in enhancing your production capabilities, feel free to reach out for more information!

Wood crusher machine for sale

When considering a Wood Crusher Machine for sale, it’s important to note that while many models may appear similar, they differ significantly in several key aspects. Our wood crushing machines come with a variety of options to suit your specific needs.

- Power supply options. Choose between electric motor and diesel engine types.

- Feeding ports. Available in single feeding port or double feeding port configurations.

- Inlet length. Customizable feeding inlet lengths to accommodate various materials.

- Processing capacities. Different sizes of wood crushing machines are designed for varying processing capacities.

Additionally, we offer a selection of screen mesh sizes, allowing you to customize the output to meet your requirements. Whether you’re looking for high efficiency or specific operational features, our wood crusher machines are designed to deliver optimal performance tailored to your business needs. For more details, feel free to contact us!

Wood crushing machine with electric power

In order to use electricity safely and stably, the electric wood crusher above 600 needs to be equipped with a control cabinet. The motor-type pulverizer can be equipped with wheels according to customer needs to increase mobility.

Parameters of wood shredding machine with electric motor

| Mfano | Uwezo | Electric Power | Feeding size |

| WD-420 | 300-400 kg/h | 11kw | 10cm |

| WD-500 | 500-600kg/h | 18.5kW | 15cm |

| WD-600 | 800-1000kg/h | 30kw | 17cm |

| WD-700 | 1200-1500kg/h | 37kw | 20cm |

| WD-900 | 2000-2500kg/h | 55kw | 22cm |

| WD-1000 | 3000-3500kg/h | 75kw | 26cm |

| WD-1200 | 3500-4000kg/h | 90kw | 28-30cm |

Type 420, 500, and 600 electric wood crushers are named after the diameter of the cutter head in the shredder. Small-scale wood crushing equipment has less investment and suitable output, which can meet customer needs. Because small-scale wood crusher machines are small in size, they also pay less sea freight, which is more economical.

Diesel power wood crusher

The diesel engine-type wood shredding machine has more flexible application scenarios. It is not limited by the power supply and is widely used in garden work, forest farm work, and places where the voltage is unstable. We can also install wheels under the crusher, which greatly improves mobility.

Parameters of diesel power wood crusher

| Mfano | Uwezo | Diesel power | Feeding size |

| WD-420 | 300-400 kg/h | 15hp | 10cm |

| WD-500 | 500-600kg/h | 30hp | 15cm |

| WD-600 | 800-1000kg/h | 60hp | 17cm |

| WD-700 | 1200-1500kg/h | 60hp | 20cm |

| WD-900 | 2000-2500kg/h | 80hp | 22cm |

| WD-1000 | 3000-3500kg/h | 110hp | 26cm |

| WD-1200 | 3500-4000kg/h | 132hp | 28-30cm |

The 420, 500, and 600 models are named after the diameter of the cutter head in the shredder, for example, the 500 model has a cutter head diameter of 500 mm. Other large models are named by the manufacturers themselves. 420, 500 and 600 models can satisfy most customers due to their low price and production volume.

Specially customized sawdust making machine

To enhance the convenience of using wood shredding machines, we offers customization options for our wood crushers. We understand that different materials may require specific feeding configurations, and we provide tailored solutions to meet these needs.

- Special feeding ports. We can customize wood crushers with double inlets for more efficient feeding.

- Enlarged feed ports. An enlarged feeding port design allows for easier loading of materials.

- Flat feed port. Ideal for soft materials, such as corn stalks, ensuring smooth processing.

These customization options are designed to improve the user experience and streamline the feeding process. If you’re interested in enhancing your wood shredding operations, please reach out for more information!

Features of wood crushing machine

- Compact structure: Small footprint for easy operation and space saving.

- Precision balancing: Rotors are dynamically balanced for low vibration.

- Automatic feeding: Improves efficiency and reduces labor time.

- Power options: Electric or diesel engine; single or double inlet available.

- Mobility: Optional two-wheel design for easy transport.

- Dust control: Optional sand cyclone and dust removal for cleaner operation.

- Versatile screens: Multiple mesh sizes for adjustable particle output.

- Customization: Tailored solutions to meet specific requirements.

These features make our wood crushing machine a highly efficient and adaptable choice for various applications.

Structure of wood shredding machine

The wood crusher machine for sale is designed with a robust structure that includes several key components. Each part plays a vital role in the effective processing of raw materials into sawdust.

- Base. Provides stability and support for the entire machine.

- Motor. Available in two power supply options—electric motor and diesel engine—allowing you to choose based on your specific needs.

- Belt. Connects the motor to the operational components, ensuring efficient power transmission.

- Feeding port. Allows for the introduction of raw materials into the machine.

- Blades. Cut the raw materials into smaller pieces, initiating the crushing process.

- Hammers. A further crush the wood into sawdust until it meets the desired size.

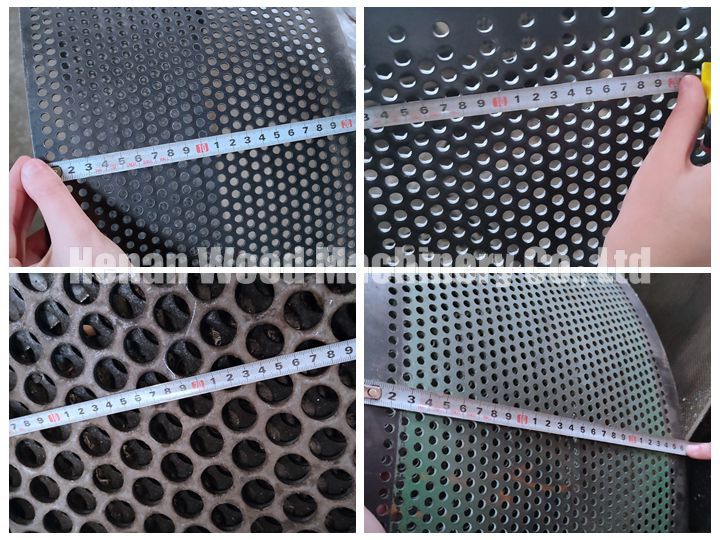

- Screen mesh. Unifies the sawdust size for consistent reprocessing. Made of carbon steel, the hole sizes typically range from 3 to 12 mm.

- Discharge port. Facilitates the exit of processed sawdust from the machine.

It’s important to note that the blades, hammers, and screen are considered wearing parts, so it’s advisable to keep extra replacements on hand for long-term use. This comprehensive structure ensures that the wood shredding machine operates efficiently and effectively.

Video of wood crushing equipment working in a forest farm

Applications of sawdust making machine

The multi-functional wood crushing equipment, featuring two feeding ports, is capable of processing a diverse range of materials. This versatility enables it to crush both hard and soft substances efficiently.

- Hard materials. Can crush tougher woods, including logs, pine, miscellaneous wood, yang mu, fir, raw bamboo, nutshells, and bark.

- Soft materials. Also effective for softer materials like straw, thatch, corn, and crop stalks.

The processed wood raw materials have numerous applications, including:

- Production of charcoal. Sawdust can be carbonized in a furnace ya kaboni to create charcoal.

- Plywood manufacturing. Suitable for making various plywood products.

- Paper production. Can be utilized in the manufacturing of paper.

- Fuel production. Sawdust can be pressed into sticks using a biomass briquettes making machine for use as fuel.

This wide array of applications not only enhances productivity but also promotes the effective utilization of wood waste in various industries.

Precautions in using the wood crusher

When operating the wood crusher, it’s essential to follow these precautions to ensure safety and optimal performance:

- Power check: Ensure correct motor rotation before operation.

- Cutter setup: Knife edge should extend 2–4 mm from the plate surface.

- Bolt maintenance: Replace worn pressure bolts promptly to avoid slippage.

- Knife length: Keep all knives at consistent length.

- Material check: Do not feed wood with stones or nails.

- Sharpening: Maintain a 28–30° angle; avoid convex grinding surfaces.

By adhering to these precautions, you can ensure the longevity and efficiency of your wood crusher.

Feel free to contact us!

In summary, the Wood Crusher Machine efficiently turns various raw materials into valuable sawdust.

With durable design and customizable options, it handles both hard and soft materials, making it ideal for charcoal, plywood, and paper industries.

Investing in this machine boosts efficiency and promotes waste recycling—contact us for details and pricing to upgrade your production today!