Mstari wa Uzalishaji wa Briquettes za Makaa ya Kuni | Mstari wa Kuunda Mchanganyiko wa Makaa ya Kuni

Mstari wa utengenezaji wa briquettes za makaa ya mawe ni mchakato wa kubandika makaa yaliyosagwa kuwa briquettes za mduara au za mshipa. Vifaa vya mstari wa kuunda unga wa makaa ya mawe vinajumuisha crusher ya makaa, mchanganyiko wa mshipa wa mshipa mbili, mashine ya kubandika makaa, kavu na mashine ya kufungasha. Briquettes zinazozalishwa zinaweza kutumika sana katika matumizi ya nyumbani na ya viwandani. Mashine za WOOD zinaweza kubinafsisha mashine na viambato kulingana na mahitaji tofauti ya wateja, na pia zinaweza kurekebisha na kubinafsisha mashine za mstari wa uzalishaji.

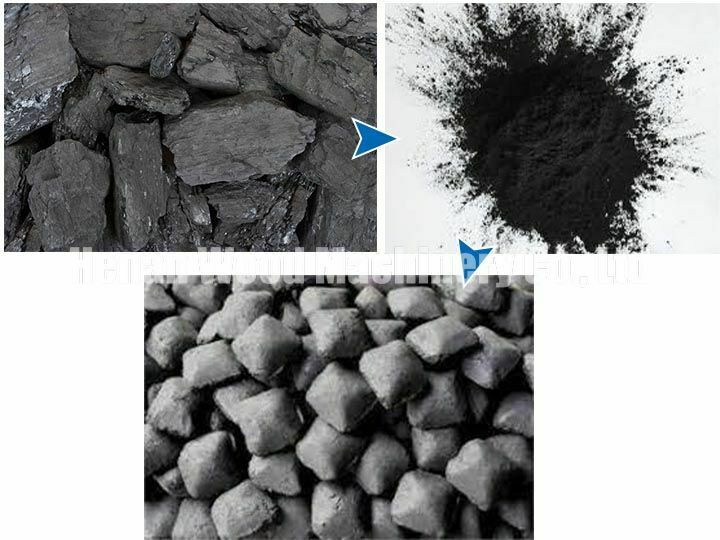

Malighafi ya mstari wa utengenezaji wa briquettes za makaa ya mawe

Malighafi ya mstari wa utengenezaji wa briquettes za makaa ya mawe ni makaa, kisha makaa huunguzwa kuwa unga mdogo wa makaa. Kabla ya kuunda, makaa yaliyosagwa yanahitaji kuchanganywa na kiambato na maji kwa uwiano fulani, ili kuongeza unene wa briquettes na kusaidia makaa yaliyosagwa kuunda vizuri.

Hatua kuu za mstari wa kuunda unga wa makaa ya mawe

Kusaga–Kuchanganya–Kuzalisha–Kua–Kufungasha

Hatua ya 1: Kusaga

Kipande kikandamizaji cha makaa kinafaa kwa vifaa vya ujenzi, madini, metallurgy, viwanda vya kemikali, na sekta nyingine. Kawaida kinatumika kusaga mawe ya chokaa, makaa, na madini mengine. Katika mstari huu wa utengenezaji wa briquettes za makaa ya mawe, huvirundika makaa kuwa unga mdogo wa makaa, ambao huingizwa kupitia conveyor ya mkanda kwenye mchanganyiko wa mshipa mara mbili.

Hatua ya 2: Kuchanganya

Katika hatua hii, changanya unga wa makaa ya mawe, kiambato na maji pamoja. Weka viambato hivi vitatu kwenye mchanganyiko wa mshipa wa mshipa mbili kwa uwiano fulani ili kuchanganya.

Hatua ya 3: Kuunda

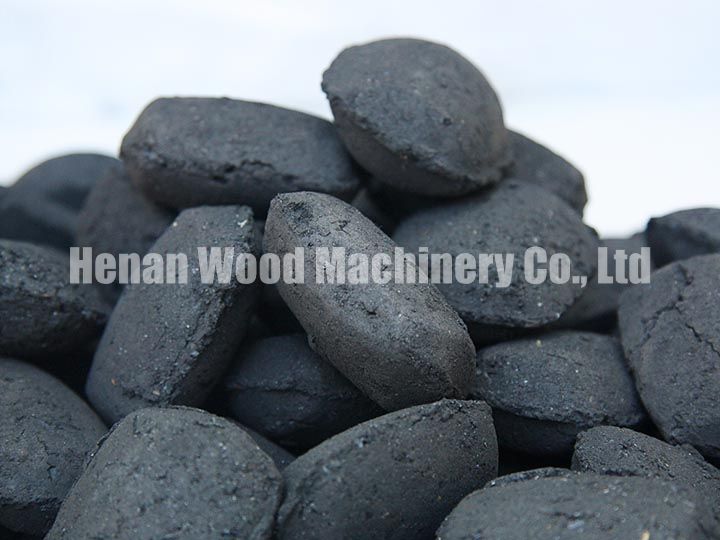

Mashine ya kubandika makaa ya mawe inatumia rollers mbili kubandika makaa yaliyosagwa na kutoa briquettes za makaa ya mawe zenye msongamano mkubwa kwa shinikizo kubwa. Kiwango kikubwa cha mfano wa mashine, ndivyo shinikizo linavyokuwa kikubwa na pato linakuwa kikubwa. Briquette inaweza kubuniwa kuwa ya mduara, mshipa, mraba, na kadhalika. Mashine hii inatumika sana katika tasnia ya makaa na tasnia ya metallurgi.

Hatua ya 4: Kua

Kwa sababu ya kuongeza maji na kiambato, briquettes zilizotayarishwa zitakuwa na unyevu mkubwa, ambao utaathiri ufanisi wa kuchoma. Kwa hivyo, briquettes za makaa yanahitaji kukauka kwa kutumia kavu ili kupunguza unyevu. Mashine za WOOD zina aina mbili za kavu, moja ni kavu wa sanduku, nyingine ni kavu wa mkanda wa mesh.

Hatua ya 5: Kufungasha

Briquettes zilizokaushwa zinaweza kufungashwa kwa mashine ya kufungasha yenye uzito. Weka uzito kwanza, na mashine itaacha kutoa baada ya uzito kufikia kiwango.

Maombi ya briquettes za makaa ya mduara na za mshipa

Mstari wa kuunda unga wa makaa ya mawe unaweza kuzalisha briquettes za mduara, za mshipa, na za mraba. briquettes za makaa ya mkaa Kwa ujumla, wateja wanapendelea kutumia briquettes za mduara na za mshipa kwa sababu za vitendo na bei.

Briquette inajumuisha briquettes za matumizi ya nyumbani na za viwandani. Briquettes za matumizi ya nyumbani zinahusisha makaa yanayotumika katika maisha ya kila siku, ikiwa ni pamoja na kupikia, kupasha joto, na huduma za mapishi. Utengenezaji wa briquette za viwandani ni mchakato mgumu zaidi na una mahitaji makubwa. Kwa ujumla, huzingatia makaa ya mduara, briquette ya boiler, na briquette rafiki wa mazingira.

Badilisha makaa kuwa nishati safi

Makaa safi hutengenezwa kwa kusindika makaa kwa teknolojia ya kisasa, kuongezea viambato na vitu vya kemikali. Mstari wa utengenezaji wa briquettes za makaa ya mawe unaweza kukamilisha hatua zote za usindikaji kwa urahisi, wafanyakazi wanahitaji tu kuvirundikia viwango sahihi vya viambato kwenye mchanganyiko, na mashine hufanya mengine.

Ikilinganishwa na makaa ya kawaida, kiwango sawa cha kuchoma kinaweza kupunguza sana utoaji wa vichafuzi kama dioksidi sulfuri, oksidi za nitrojeni, na vumbi, ambayo ni safi zaidi ikilinganishwa. Kila msimu wa baridi ni kipindi kigumu cha uchafuzi wa hewa, ambapo matumizi ya makaa ya moto kwa wakazi ni mojawapo ya vyanzo vikuu vya uchafuzi. Kukuza matumizi ya makaa safi kunaweza kupunguza kwa ufanisi shinikizo la joto la majira ya baridi na kujenga mfumo wa joto safi.

Maonyesho ya mashine za kiwanda za kuunda unga wa makaa ya mawe

Kiwanda chetu kina hisa ya kutosha na modeli mbalimbali zinapatikana kwa urahisi. Ikiwa wateja wana mahitaji maalum kuhusu uzalishaji au umbo la mstari wa utengenezaji wa briquettes, tunaweza kubuni na kubinafsisha.

Mshindi wa kesi ya mafanikio ya mstari wa utengenezaji wa briquettes za makaa ya mawe kwa Romania

Mteja kutoka Romania aliona video ya mashine yetu ya kubandika makaa ya mkaa kwenye YouTube, akabonyeza kutembelea channel yetu na kufurahi kuona mashine aliyotaka. Kisha alishauriana na meneja wetu wa mauzo kuhusu mstari wa uzalishaji unaohusiana, baada ya kujua mahitaji yake, tulimshauri kuhusu mstari huu wa utengenezaji wa briquettes za makaa ya mawe. Sasa mstari wote wa uzalishaji umekusafirishwa kwenda Romania.

Huduma za uuzaji wa mstari wa kuunda unga wa makaa ya mawe

- Huduma za awali: Kukupatia upangaji wa mradi, muundo wa mchakato, na kuendeleza seti ya vifaa vinavyokufaa; kubuni na kutengeneza mstari wa kuunda unga wa makaa ya mawe kulingana na mahitaji yako maalum, na kutoa mafunzo kwa ajili ya uendeshaji wa kiufundi na matengenezo.

- In-sale service: Precise production equipment, and accompany our customer to complete the acceptance of the equipment, assist in the preparation of the installation plan, and detailed process.

- Kampuni yetu itatuma wahandisi kwa tovuti za wateja ili kuongoza usakinishaji wa vifaa, kuendesha mashine ya utengenezaji wa briquettes za makaa ya mawe kwa uzalishaji wa kawaida, na kuwafundisha wafanyakazi matumizi na matengenezo.