آلة كسارة الخشب للبيع | آلة تقطيع نفايات الخشب

| ماركة | ماكينات Shuliy |

| معامل | 300-4000 كجم/ساعة |

| طريقة القوة | المحركات الكهربائية ومحركات الديزل |

| تخصيص الخدمة | تصميم المدخل وطريقة الحركة |

| ضمان | 12 شهر |

يمكن لآلة كسارة الخشب إنتاج نشارة الخشب من مواد خام مختلفة، بما في ذلك الخشب والفروع والخيزران. تم تصميم هذه الآلة للتعامل مع مجموعة من المواد مثل سيقان الصنوبر والتنوب والذرة، وتحولها إلى نشارة خشب عالية الجودة.

مع قدرة تتراوح من 300 إلى 4000 كجم/ساعة، فإنه يوفر إنتاجية مذهلة مع الحفاظ على استهلاك منخفض للطاقة. المعدات ليست سهلة التركيب والتشغيل فحسب، بل تتطلب أيضًا الحد الأدنى من الصيانة، مما يجعلها حلاً فعالاً من حيث التكلفة للشركات.

يمكن معالجة نشارة الخشب هذه إلى منتجات مثل الفحم والخشب الرقائقي والورق. إذا كنت مهتمًا بتعزيز قدراتك الإنتاجية، فلا تتردد في التواصل معنا للحصول على مزيد من المعلومات!

آلة طحن الخشب للبيع

عند التفكير في بيع آلة كسارة الخشب، من المهم ملاحظة أنه على الرغم من أن العديد من النماذج قد تبدو متشابهة، إلا أنها تختلف بشكل كبير في العديد من الجوانب الرئيسية. تأتي آلات سحق الخشب لدينا مع مجموعة متنوعة من الخيارات لتناسب احتياجاتك الخاصة.

- خيارات إمدادات الطاقة. اختر بين أنواع المحركات الكهربائية ومحركات الديزل.

- منافذ التغذية. متوفر في منفذ تغذية واحد أو تكوينات منفذ تغذية مزدوج.

- طول المدخل. أطوال مدخل التغذية قابلة للتخصيص لاستيعاب المواد المختلفة.

- قدرات المعالجة. تم تصميم أحجام مختلفة من آلات سحق الأخشاب لقدرات معالجة مختلفة.

بالإضافة إلى ذلك، نحن نقدم مجموعة مختارة من أحجام شبكات الشاشة، مما يسمح لك بتخصيص الإخراج لتلبية متطلباتك. سواء كنت تبحث عن كفاءة عالية أو ميزات تشغيلية محددة، فقد تم تصميم آلات طحن الخشب لدينا لتقديم الأداء الأمثل المصمم خصيصًا لتلبية احتياجات عملك. لمزيد من التفاصيل، لا تتردد في الاتصال بنا!

آلة طحن الخشب بالطاقة الكهربائية

من أجل استخدام الكهرباء بأمان وثبات، يجب أن تكون كسارة الخشب الكهربائية فوق 600 مجهزة بخزانة تحكم. يمكن تجهيز آلة الطحن من النوع المحرك بعجلات وفقًا لاحتياجات العميل لزيادة القدرة على الحركة.

معلمات آلة تقطيع الخشب بمحرك كهربائي

| نموذج | سعة | الطاقة الكهربائية | حجم التغذية |

| ود-420 | 300-400 كجم/ساعة | 11 كيلو واط | 10 سم |

| ود-500 | 500-600 كجم/ساعة | 18.5 كيلو واط | 15 سم |

| ود-600 | 800-1000 كجم/ساعة | 30 كيلو واط | 17 سم |

| ود-700 | 1200-1500 كجم/ساعة | 37 كيلو واط | 20 سم |

| ود-900 | 2000-2500 كجم/ساعة | 55 كيلو واط | 22 سم |

| ود-1000 | 3000-3500 كجم/ساعة | 75 كيلو واط | 26 سم |

| ود-1200 | 3500-4000 كجم/ساعة | 90 كيلو واط | 28-30 سم |

تتم تسمية كسارات الخشب الكهربائية من النوع 420 و500 و600 على اسم قطر رأس القطع في آلة التقطيع. معدات سحق الأخشاب صغيرة الحجم لديها استثمار أقل وإنتاج مناسب، مما يمكن أن يلبي احتياجات العملاء. نظرًا لأن آلات طحن الخشب صغيرة الحجم صغيرة الحجم، فإنها تدفع أيضًا رسوم شحن بحري أقل، وهو أكثر اقتصادا.

كسارة الخشب تعمل بالديزل

تتميز آلة تقطيع الخشب من نوع محرك الديزل بسيناريوهات تطبيق أكثر مرونة. لا يقتصر على مصدر الطاقة ويستخدم على نطاق واسع في أعمال الحدائق وأعمال مزرعة الغابات والأماكن التي يكون فيها الجهد غير مستقر. يمكننا أيضًا تركيب العجلات أسفل الكسارة، مما يحسن الحركة بشكل كبير.

معلمات كسارة الخشب بقوة الديزل

| نموذج | سعة | طاقة الديزل | حجم التغذية |

| ود-420 | 300-400 كجم/ساعة | 15 حصان | 10 سم |

| ود-500 | 500-600 كجم/ساعة | 30 حصان | 15 سم |

| ود-600 | 800-1000 كجم/ساعة | 60 حصان | 17 سم |

| ود-700 | 1200-1500 كجم/ساعة | 60 حصان | 20 سم |

| ود-900 | 2000-2500 كجم/ساعة | 80 حصان | 22 سم |

| ود-1000 | 3000-3500 كجم/ساعة | 110 حصان | 26 سم |

| ود-1200 | 3500-4000 كجم/ساعة | 132 حصان | 28-30 سم |

تمت تسمية الطرازات 420 و500 و600 على اسم قطر رأس القاطع في آلة التقطيع، على سبيل المثال، يحتوي الطراز 500 على قطر رأس قاطع يبلغ 500 مم. تتم تسمية النماذج الكبيرة الأخرى من قبل الشركات المصنعة نفسها. يمكن لنماذج 420، 500 و600 أن ترضي معظم العملاء نظرًا لسعرها المنخفض وحجم إنتاجها.

آلة صنع نشارة الخشب مخصصة خصيصا

لتعزيز سهولة استخدام آلات تكسير الخشب، نقدم خيارات تخصيص لكسّارات الخشب لدينا. نحن ندرك أن المواد المختلفة قد تتطلب تكوينات تغذية محددة، ونقدم حلولاً مصممة لتلبية هذه الاحتياجات.

- منافذ تغذية خاصة. يمكننا تخصيص كسارات الخشب بمداخل مزدوجة من أجل تغذية أكثر كفاءة.

- منافذ تغذية موسعة. يسمح تصميم منفذ التغذية الموسع بتحميل المواد بشكل أسهل.

- منفذ تغذية مسطح. مثالية للمواد الناعمة، مثل سيقان الذرة، مما يضمن المعالجة السلسة.

تم تصميم خيارات التخصيص هذه لتحسين تجربة المستخدم وتبسيط عملية التغذية. إذا كنت مهتمًا بتعزيز عمليات تمزيق الأخشاب لديك، فيرجى التواصل معنا للحصول على مزيد من المعلومات!

مميزات آلة طحن الخشب

- هيكل مدمج: مساحة صغيرة لتسهيل التشغيل وتوفير المساحة.

- موازنة دقيقة: المراوح متوازنة ديناميكيًا لخفض الاهتزاز.

- التغذية التلقائية: يحسن الكفاءة ويقلل من وقت العمل.

- خيارات الطاقة: محرك كهربائي أو ديزل؛ متاح مدخل واحد أو مزدوج.

- التنقل: تصميم بعجلتين اختياري لسهولة النقل.

- التحكم في الغبار: اختياري دوامة الرمل وإزالة الغبار لعملية أنظف.

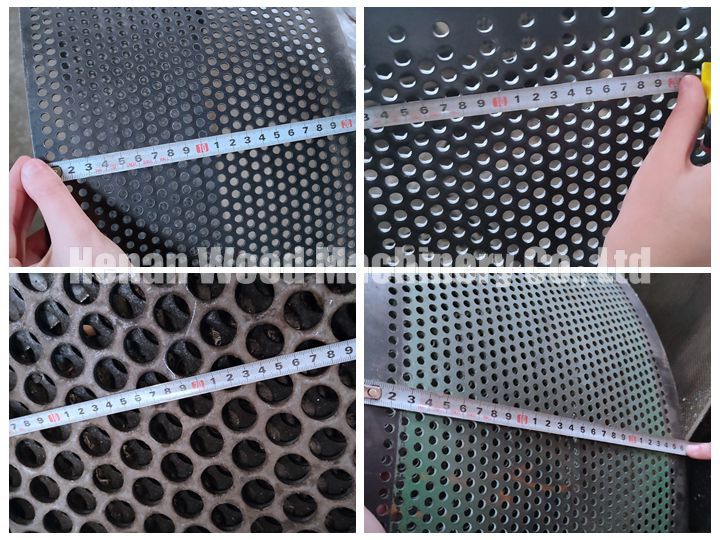

- شاشات متعددة الاستخدامات: أحجام شبكية متعددة لإخراج جزيئات قابل للتعديل.

- التخصيص: حلول مخصصة لتلبية المتطلبات الخاصة.

هذه الميزات تجعل آلة تكسير الخشب الخاصة بنا خيارًا عالي الكفاءة وقابل للتكيف لمختلف التطبيقات.

هيكل آلة تقطيع الخشب

تم تصميم آلة كسارة الخشب للبيع بهيكل قوي يتضمن العديد من المكونات الرئيسية. يلعب كل جزء دورًا حيويًا في المعالجة الفعالة للمواد الخام وتحويلها إلى نشارة الخشب.

- قاعدة. يوفر الاستقرار والدعم للجهاز بأكمله.

- محرك. متوفر في خيارين لإمدادات الطاقة - محرك كهربائي ومحرك ديزل - مما يسمح لك بالاختيار بناءً على احتياجاتك الخاصة.

- حزام. يربط المحرك بالمكونات التشغيلية، مما يضمن نقل الطاقة بكفاءة.

- منفذ التغذية. يسمح بإدخال المواد الخام إلى الآلة.

- شفرات. قطع المواد الخام إلى قطع أصغر، لبدء عملية السحق.

- المطارق. ثم قم بسحق الخشب إلى نشارة الخشب حتى يصل إلى الحجم المطلوب.

- شبكة الشاشة. يوحد حجم نشارة الخشب لإعادة المعالجة المتسقة. تتراوح أحجام الفتحات المصنوعة من الفولاذ الكربوني عادة من 3 إلى 12 ملم.

- منفذ التفريغ. يسهل خروج نشارة الخشب المعالجة من الماكينة.

من المهم ملاحظة أن الشفرات والمطارق والشاشة تعتبر أجزاء قابلة للتآكل، لذا يُنصح بالاحتفاظ ببدائل إضافية في متناول اليد للاستخدام على المدى الطويل. يضمن هذا الهيكل الشامل أن آلة تقطيع الخشب تعمل بكفاءة وفعالية.

فيديو لمعدات تكسير الأخشاب التي تعمل في مزرعة غابات

تطبيقات آلة صنع نشارة الخشب

إن معدات سحق الخشب متعددة الوظائف، والتي تتميز بمنفذين للتغذية، قادرة على معالجة مجموعة متنوعة من المواد. يتيح هذا التنوع إمكانية سحق المواد الصلبة والناعمة بكفاءة.

- المواد الصلبة. يمكنه سحق الأخشاب الأكثر صلابة، بما في ذلك جذوع الأشجار والصنوبر والأخشاب المتنوعة واليانغ مو، التنوبوالخيزران الخام وقشور الجوز واللحاء.

- مواد ناعمة. فعال أيضًا مع المواد الأكثر ليونة مثل القش والقش والذرة وسيقان المحاصيل.

المواد الخام الخشبية المعالجة لها تطبيقات عديدة، بما في ذلك:

- إنتاج الفحم . يمكن تفحيم نشارة الخشب في فرن الكربنة لإنشاء الفحم.

- تصنيع الخشب الرقائقي. مناسبة لصنع منتجات الخشب الرقائقي المختلفة.

- إنتاج الورق. يمكن استخدامه في صناعة الورق.

- إنتاج الوقود. يمكن ضغط نشارة الخشب على شكل أعواد باستخدام أ آلة صنع قوالب الكتلة الحيوية لاستخدامها كوقود.

هذه المجموعة الواسعة من التطبيقات لا تعزز الإنتاجية فحسب، بل تعزز أيضًا الاستخدام الفعال لنفايات الخشب في مختلف الصناعات.

الاحتياطات في استخدام كسارة الخشب

عند تشغيل كسارة الخشب، من الضروري اتباع هذه الاحتياطات لضمان السلامة والأداء الأمثل:

- فحص الطاقة: تأكد من دوران المحرك الصحيح قبل التشغيل.

- إعداد القاطع: يجب أن يمتد حافة السكين من 2 إلى 4 مم من سطح اللوحة.

- صيانة البراغي: استبدل البراغي ذات الضغط البالية بسرعة لتجنب الانزلاق.

- طول السكين: حافظ على جميع السكاكين بطول متناسق.

- فحص المادة: لا تغذي الخشب بالحجارة أو المسامير.

- توضيح: حافظ على زاوية 28–30°؛ تجنب الأسطح المقعرة للطحن.

من خلال الالتزام بهذه الاحتياطات، يمكنك ضمان طول عمر وكفاءة كسارة الخشب الخاصة بك.

لا تتردد في الاتصال بنا!

في الختام، تقوم آلة تكسير الخشب بكفاءة بتحويل مواد خام متنوعة إلى نشارة خشب ثمينة.

بتصميم متين وخيارات قابلة للتخصيص، يتعامل مع المواد الصلبة والناعمة، مما يجعله مثالياً لصناعات الفحم والخشب الرقائقي والورق.

الاستثمار في هذه الآلة يعزز الكفاءة ويروّج لإعادة تدوير النفايات—تواصل معنا لمعرفة التفاصيل والأسعار لترقية إنتاجك اليوم!