What materials are suitable for the biomass briquette forming machine?

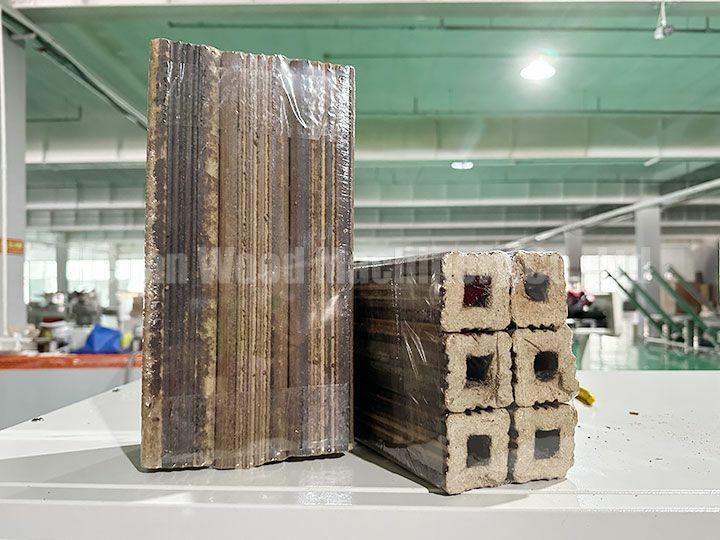

The biomass briquette forming machine can convert various types of biomass waste into high-density solid fuel briquettes.

These briquettes can be used as an eco-friendly alternative to traditional fuels like firewood and coal, offering better combustion efficiency, reduced pollution, and easier storage and transportation.

So, what materials are suitable for the biomass briquette forming machine?

Wood-based materials

The most common and ideal raw materials for biomass briquetting machines are wood-derived wastes. These include:

- ሳር — from sawmills, furniture factories, and wood processing.

- የእንጨት ቺፕስ እና የእንጨት መላጨት — from cutting, planing, or wood manufacturing.

- Bark and small branches — these can be mixed with sawdust to improve briquette quality.

These materials are rich in lignin, a natural binder that helps particles fuse under heat and pressure during briquetting.

Agricultural residues

Biomass briquette machines are also capable of processing a wide range of agricultural by-products, making them versatile for different regions and industries. Common examples include:

- Rice husks እና corn stalks

- ገለባ እና bagasse (sugar cane residue)

- የኦቾሎኒ ዛጎሎች, የኮኮናት ቅርፊቶች, እና coffee husks

- ቅጠሎች እና other crop residues

These materials are often abundant and underutilized, providing an excellent feedstock for fuel briquettes after proper size reduction and drying.

Mixed biomass waste

Beyond wood and crop residues, many other organic wastes can be briquetted, often after initial processing:

- Bamboo chips

- Tree pruned branches

- Plant fibers and husks

While some biomass types (like leaves or bark) may not pack well on their own due to low binding properties, blending them with materials like sawdust ensures optimal briquette formation and density.

Material preparation requirements

To achieve high-quality briquettes, raw materials generally need to meet specific physical conditions before entering the briquetting machine:

- Appropriate particle size: Ideally below 3–5 mm, requiring crushing for larger waste like branches.

- Low moisture content: Typically controlled below 8–12% — excess moisture can hinder molding and reduce briquette quality.

- No added binders (for many systems): Many biomass machines rely on natural lignin and pressure for bonding.

Why are these materials suitable for the biomass briquette forming machine?

These biomass materials are effective in briquette forming because:

- They contain natural binders (like lignin) that activate under heat and pressure.

- They are renewable and widely available as by-products of agriculture and wood processing.

- They can be transformed into stable, high-density fuel rods suitable for heating, industrial energy, or further carbonization into charcoal briquettes.

ማጠቃለያ

In conclusion, a biomass briquette forming machine is highly adaptable and can process a wide range of wood waste, agricultural residues, and mixed biomass materials. As long as the raw materials are properly crushed and dried, they can be efficiently compressed into high-density briquettes with excellent combustion performance.

By turning low-value biomass waste into clean, renewable fuel, biomass briquetting machines not only improve resource utilization but also support sustainable and cost-effective energy production for various industries.