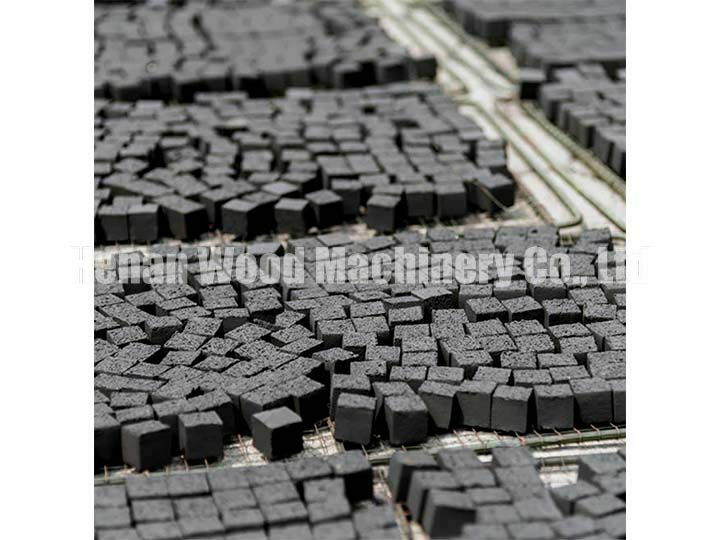

Machine à fabriquer du charbon de chicha carré exportée aux États-Unis

Au début de cette année, notre Machine à fabriquer du charbon de narguilé carré a été exportée avec succès vers les États-Unis pour un fabricant professionnel de produits en charbon, spécialisé dans le charbon pour narguilé et shisha.

Le client visait à moderniser son processus de production pour améliorer l'efficacité, la cohérence du produit et la stabilité de la production pour le marché local en croissance.

Contexte client et objectifs d'achat

Le client américain est depuis longtemps engagé dans la production et la fourniture de charbon de narguilé carré pour les salons de narguilé, les distributeurs et les marques de détail.

Avant d'acheter la machine, le client s'est principalement concentré sur les questions suivantes :

- La machine peut-elle produire du charbon de narguilé carré avec une taille et une densité constantes ?

- Quelle est la capacité de production, et est-elle adaptée à une opération continue ?

- Quel est le degré d'automatisation de la machine, et quelle quantité de main-d'œuvre est requise ?

- La machine est-elle facile à utiliser et à entretenir ?

- La machine peut-elle être personnalisée pour répondre aux normes du marché américain ?

Machine de fabrication de charbon de chicha carré à vendre

En fonction des besoins de production du client, nous avons recommandé notre Machine à fabriquer du charbon de narguilé carré, spécialement conçue pour presser des briquettes de charbon de narguilé carrées à haute densité. Cette machine est largement utilisée pour traiter la poudre de charbon provenant de coquilles de noix de coco, de bois dur ou de biomasse mixte.

Principaux paramètres techniques

| Type de machine | Machine à fabriquer du charbon de narguilé carré |

| Pouvoir | 15 kW |

| Capacité de production | 44 pièces par presse × 4 presses par minute |

| Efficacité de production | Environ 170–180 pièces par minute |

| Taille de la machine | 850 × 2000 × 2100 mm |

| Poids de la machine | Environ 2,8 tonnes |

| Forme de la briquette | Carré (moule personnalisable) |

Caractéristiques clés appréciées par le client

Briquettes à haute densité et uniformes

La machine adopte un système de formation à haute pression pour garantir que chaque briquette de charbon carré ait une taille uniforme, une haute densité et un faible taux de casse. Cela contribue à améliorer la durée de combustion et la qualité globale du produit, ce qui est particulièrement important pour le marché du charbon de narguilé.

Moules carrés personnalisables

Pour répondre aux préférences du marché américain, la machine supporte des tailles de moules carrés personnalisés telles que 20×20×20 mm et 25×25×25 mm, permettant au client de répondre de manière flexible à différents besoins d'emballage et de branding.

Haute automatisation et économie de main-d'œuvre

La machine dispose d'un alimentation automatique et d'une presse continue. Un opérateur suffit pour faire fonctionner l'équipement, réduisant considérablement les coûts de main-d'œuvre tout en améliorant l'efficacité de la production.

Facile à utiliser et à entretenir

La structure mécanique est stable et facile à entretenir. Le nettoyage quotidien et la maintenance de routine peuvent être effectués rapidement, garantissant un fonctionnement à long terme et stable.

Retour client après installation

Après l'installation et la mise en service, le client a signalé un fonctionnement stable et une production constante. Le charbon de narguilé carré produit par la machine a montré d'excellentes performances en termes de précision de la forme, de densité et de comportement de combustion.

L'efficacité de production améliorée a permis au client de répondre plus facilement aux commandes en gros, tandis que la qualité constante du produit a renforcé leur compétitivité sur le marché local américain.

Conclusion

En introduisant notre Machine à fabriquer du charbon de narguilé carré, le client américain a réussi à augmenter sa capacité de production de charbon de narguilé et la qualité du produit. La machine a fourni une solution fiable et efficace pour la fabrication à grande échelle de charbon de narguilé carré, soutenant la croissance à long terme de l'entreprise.

Si vous souhaitez en savoir plus sur les configurations de la machine, les options de personnalisation ou les lignes complètes de production de charbon de narguilé, nous sommes prêts à fournir un support technique détaillé et des solutions.